PyroGenesis Signs Additional Military Contracts of Approx. US$1.2MM; Contracts Signed Since June 30, - 500 Beiträge pro Seite | Diskussion im Forum

eröffnet am 10.01.17 18:38:07 von

neuester Beitrag 23.12.17 19:31:45 von

neuester Beitrag 23.12.17 19:31:45 von

Beiträge: 94

ID: 1.244.563

ID: 1.244.563

Aufrufe heute: 0

Gesamt: 2.386

Gesamt: 2.386

Aktive User: 0

ISIN: CA74734T1049 · WKN: A12DDL · Symbol: PYR

0,4600

CAD

+2,22 %

+0,0100 CAD

Letzter Kurs 19.04.24 Toronto

Neuigkeiten

17.04.24 · globenewswire |

17.04.24 · globenewswire |

11.04.24 · globenewswire |

11.04.24 · globenewswire |

10.04.24 · globenewswire |

Werte aus der Branche Dienstleistungen

| Wertpapier | Kurs | Perf. % |

|---|---|---|

| 1,4000 | +35,92 | |

| 1,3200 | +29,41 | |

| 0,5100 | +27,50 | |

| 1,9500 | +26,62 | |

| 7,4700 | +22,06 |

| Wertpapier | Kurs | Perf. % |

|---|---|---|

| 9,8500 | -15,81 | |

| 1,6800 | -22,58 | |

| 0,6300 | -30,00 | |

| 1,1700 | -30,36 | |

| 0,7103 | -56,69 |

MONTREAL, QUEBEC--(Marketwired - Jan. 10, 2017) - PyroGenesis Canada Inc. (http://pyrogenesis.com) (TSX VENTURE:PYR)(OTCQB:PYRNF), a clean-tech company (the "Company" or "PyroGenesis") that designs, develops, manufactures and commercializes plasma …

Lesen Sie den ganzen Artikel: PyroGenesis Signs Additional Military Contracts of Approx. US$1.2MM; Contracts Signed Since June 30, 2016 Now Exceed CAN$13MM

Lesen Sie den ganzen Artikel: PyroGenesis Signs Additional Military Contracts of Approx. US$1.2MM; Contracts Signed Since June 30, 2016 Now Exceed CAN$13MM

More Revenues ... this compnay is haeding towards EPS !

Updates from PyroGenesis on Powder Production, Additive Manufacturing Spinoff Company

https://3dprint.com/162551/pyrogenesis-powder-am-updates/Interessante Aktie.

Mal sehen wie sich der Kurs von PyroGenesis entwickelt, sobald die ersten Pülverchen produziert und verkauft werden.

Our seas have become a plastic graveyard - but can technology turn the tide?

http://www.telegraph.co.uk/science/2017/02/11/seas-have-beco…The Canadian company behind the system, called PyroGenesis

Link zum Twitter Account von PyroGenesis

https://twitter.com/PyroGenesisCan Single-step production of high-purity silicon demonstrated

http://www.chemengonline.com/single-step-production-of-high-…PyroGenesis Canada

Dieses Bild ist nicht SSL-verschlüsselt: [url]http://www.chemengonline.com/wp-content/uploads/2017/03/p7_1.jpg

[/url]Achieving silicon of acceptable purity for solar-energy applications typically requires several purification steps. Now, a new process has been demonstrated that can produce high-purity Si from low-quality quartz in a single step. The PureVap technology from PyroGenesis Canada Inc. (Montreal, Que.; www.pyrogenesis.com) utilizes a powerful vacuum-arc furnace, combining the carbothermic reduction of silicon and purification into one process, explains Pierre Carabin, chief technology officer for PyroGenesis Canada.

Traditional arc furnaces produce relatively low-purity Si, around 98.5% purity, requiring subsequent purification. Inside the PureVap furnace, low-quality (97.5%) quartz and a carbon source are exposed to heat from a plasma arc, creating CO2 and Si. The vacuum-arc furnace allows for the vaporization of contaminants, including boron and sulfur. By manipulating the metallic vapors’ partial pressures, the contaminants are removed.

In 2016, following successful demonstration of the PureVap process at the laboratory scale, PyroGenesis announced a contract worth over $6 million with Canadian mining company HPQ Silicon Resources, Inc. to develop a pilot plant to produce 200 metric tons per year of high-purity Si. The company expects the plant to start up in late 2017.

In January 2017, PyroGenesis announced a series of successful trials, demonstrating both the scalability and repeatability of the PureVap system, as the company begins scaling up production from grams to kilograms. “We have proven that we can remove the contaminants and make significant quantities of silicon. We’ve also proven that we can consistently produce 99.9% purity silicon. We have been able to produce, on occasion, 99.99% purity,” says Carabin. He goes on to say that the company’s current objective is to increase this purity to at least 99.999%. According to Carabin, this is the only process in the world to convert low-quality quartz into Si of higher than 99.9% purity. “As far as we know, no one else is doing purification directly from the quartz itself.”

PYROGENESIS PROVIDES UPDATE ON POWDER PRODUCTION SYSTEM

ASSEMBLY; ALL COMPONENTS RECEIVED. ON SCHEDULE FOR Q1-2017 COMPLETION MONTREAL, QUEBEC--(Marketwired – March 14, 2017) - PyroGenesis Canada Inc. (http://pyrogenesis.com) (TSX-V: PYR) (OTCQB: PYRNF), a high tech company (the “Company” or “PyroGenesis”) that designs, develops, manufactures and commercializes plasma based systems and plasma torch products, is pleased to announce today that it has received all equipment, parts and components for its powder production system (the “System”), and that the System is well into the assembly phase.

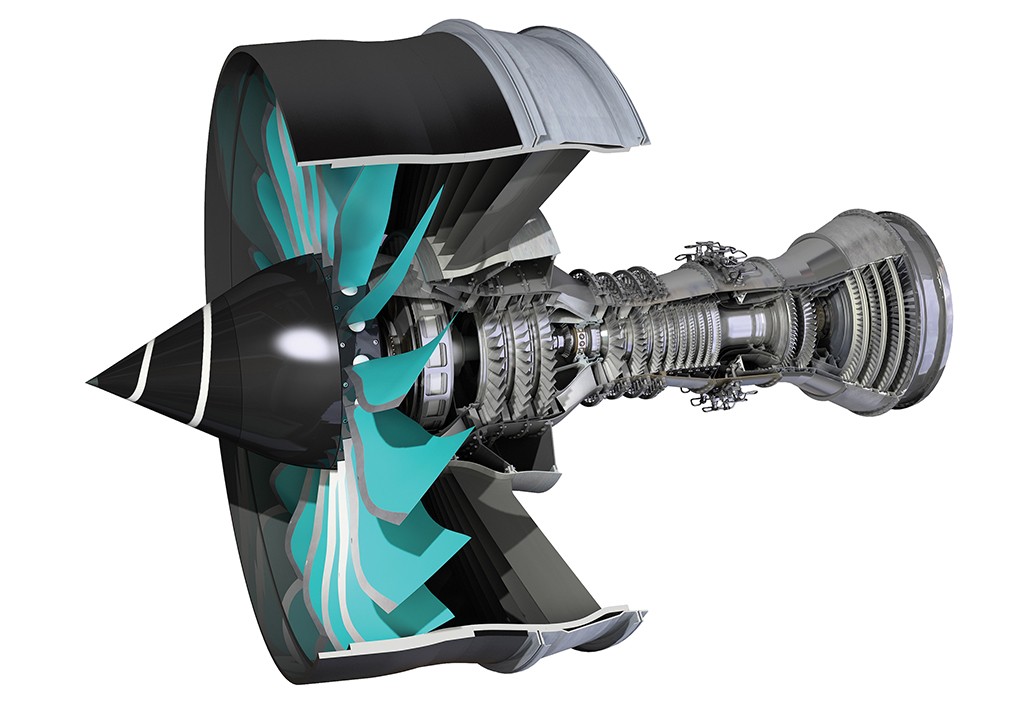

PyroGenesis’ System uses Plasma Atomization to make very pure, small, uniform, fully dense, spherical metal powders that flow like water, and which are highly sought after in the Additive Manufacturing industry.

PyroGenesis is the inventor of Plasma Atomization. The Company first began producing powders using this technology for the Biomedical industry, between 2001-2004. In 2015, PyroGenesis invested approximately $2MM in improving both the production rate and particle size distribution, which not only lead to a patent pending, but also to PyroGenesis’ decision to re-enter the market and produce powders for the Additive Manufacturing industry. The System being built today is the first of many PyroGenesis expects to make to address this increasing need for metal powders in the Additive Manufacturing industry.1

We also confirm today that the first powder run is still on schedule for the end of Q1, and that the ramp up is projected, as previously announced on January 23, 2017, to take place linearly, over the ensuing four (4) months.

“So far there have not been any unforeseen challenges during the assembly phase, and we don’t expect any during the start-up or ramp up phases”, said Mr. P. Peter Pascali, President and CEO of PyroGenesis. “What is noteworthy however, is the amount of interest we are receiving for the supply of our powders from potential customers and investors; the volume of interest from potential customers has taken us all by surprise.”

Additionally, and as previously announced, powders produced during the ramp-up phase will be available for sale. The initial focus will be on producing pure Titanium (CP Ti) and Ti-6Al-4V powders however PyroGenesis has also received interest for other metal powders and expects to attend to this as well.

“There are many factors which set us apart from all other powder producers,” said Mr. Pascali. “For one, the fact that PyroGenesis is the inventor of Plasma Atomization, and has one of the largest concentrations of plasma expertise under one roof, has enabled the Company to not only improve the process significantly, but allow it to continuously improve and thereby enable Additive Manufacturing. Let us not forget that PyroGenesis has produced Titanium powders in the past, and is not new to this prospect. Add to this the fact that there is serious consolidation taking place in the industry which is exasperating an already serious lack of powder suppliers, particulary of the characteristics we supply, all bodes well for PyroGenesis’ strategy to supply unique powders to the Additive Manufacturing industry. In short, we remain confident, and recent events have only made us more optimistic than ever before, that PyroGenesis will quickly become one of the leading metallic powder suppliers to the Additive Manufacturing (3D Printing) industry.”

http://www.pyrogenesis.com/wp-content/uploads/2017/03/UPDATE…

es geht los

PyroGenesis Announces Completion of Powder Production System; Successful First Run of Powder Production; Start of Ramp-Up; Interest exceeds Expectations.MONTREAL, QUEBEC--(Marketwired – March 30, 2017) - PyroGenesis Canada Inc. (http://pyrogenesis.com) (TSX-V: PYR) (OTCQB: PYRNF), a high-tech company (the “Company” or “PyroGenesis”) that designs, develops, manufactures and commercializes plasma waste-to-energy systems and plasma torch products, announces today that, further to its press releases of January 23, 2017 and March 14, 2017, it has completed the assembly of its first powder production system (the “System”), with the first powder run exceeding expectations and ramp-up already underway. The ramp-up is to take place linearly over approximately four (4) months.

“The first production run not only exceeded our expectations in terms of powder quality and production rate”, said Pierre Carabin, Chief Technology Officer of PyroGenesis, “but it also marked both the official start of the ramp-up period and a critical step in achieving our stated goal to become a leading supplier of high purity powders catering to the Additive Manufacturing Industry. The first powders produced were Ti-6Al-4V, one of the most sought after powder on the market. In addition, the System will allow PyroGenesis to produce other materials such as Titanium alloys and nickel based superalloy materials.”

“Although we were confident we would complete the System and first run on schedule and on budget, it is always nice to tick that box”, said P. Peter Pascali, President and CEO of PyroGenesis. “We were challenged at times by significant delays from suppliers, but it is a testament to the dedication and commitment of PyroGenesis’ team that we make this announcement today. A dedication and commitment one can expect to see throughout this project.”

PyroGenesis’ System uses Plasma Atomization to make, small, uniform, fully dense and spherical metal powders that flow like water, and which are highly sought after in the Additive Manufacturing industry.

PyroGenesis is the inventor of Plasma Atomization. The Company first began producing powders using this technology for the biomedical industry, between 2001-2004. In 2015, PyroGenesis invested approximately $2MM in improving both the production rate and particle size distribution, which not only lead to a patent pending, but also to PyroGenesis’ decision to reenter the market and produce powders for the Additive Manufacturing industry. The System is the first of many PyroGenesis expects to make to address this increasing need for metal powders in the Additive Manufacturing industry.1

Additionally, and as previously announced, powders produced during the ramp-up phase will be available for sale. The initial focus will be on producing pure Titanium (CP Ti) and Ti-6Al-4V powders however PyroGenesis has also received interest for other metal powders and expects to attend to this as well.

“What is noteworthy, beyond the technical successes announced today, is the continued interest we are receiving for the supply of our powders from potential customers, the volume of which, and from whom the interest is coming from, continues to take us all by surprise,” said Mr. Pascali. “We did not expect this type of interest before ramp-up was complete, and we would consider any sample orders (i.e. up to 500kg) made before ramp up is complete, to be very significant, and a further validation of our strategic decision to move into powder production.”

“As mentioned before, there are many factors which set us apart from all other powder producers,” added Mr. Pascali. “For one, the fact that PyroGenesis is the inventor of Plasma Atomization, and has one of the largest concentrations of plasma expertise under one roof, has enabled the Company to not only improve the process significantly, but allow it to continuously improve and thereby enable Additive Manufacturing. Let us not forget that PyroGenesis has produced Titanium powders in the past, and is not new to this prospect. Add to this the fact that there is serious consolidation taking place in the industry which is exasperating an already serious lack of powder suppliers, particularly of the characteristics we supply, all bodes well for PyroGenesis’ strategy to supply unique powders to the Additive Manufacturing industry. In short, we remain confident, and recent events including such a successful first powder production run, have only made us more optimistic than ever before, that PyroGenesis will quickly become a leading metallic powder supplier to the Additive Manufacturing (3D Printing) industry.”

http://www.pyrogenesis.com/wp-content/uploads/2017/03/Comple…

PyroGenesis Receives First Payment of $139K Under Previously Announced Military Contract

PyroGenesis Receives First Payment of $139K Under Previously Announced Military Contract for US $950,000 to Upgrade Company’s Plasma System for the Destruction of Chemical Warfare Agents MONTREAL, Quebec (Marketwired September 14, 2016) - PyroGenesis Canada Inc. (http://pyrogenesis.com) (TSX-V: PYR) (OTCQB: PYRNF), (the "Company" or "PyroGenesis") that designs, develops, manufactures and commercializes plasma waste-to-energy systems and plasma torch products, is pleased to announce today that, further to its press release of July 25, 2016, the Company has received the first payment of $139K under a previously announced military contract of US $950,000 (approx. CDN$1.25MM), wherein the Company was contracted to provide additional testing on, and further improvements to, the Company’s Tactical Mobile Plasma System used for the Destruction of Chemical Warfare Agents (the “Contract”). As announced, the Company was awaiting the Client’s approval before providing the details below.

PyroGenesis was first engaged by its client, a multi-national military consortium (the “Client”), to develop a first of its kind Tactical Mobile Plasma System (the “System”) to be used for the destruction of Chemical Warfare Agents, such as those discovered, and being dealt with, in Syria. This System has since been completed and, subsequently, PyroGenesis was awarded, and now completed, two (2) additional contracts relating to the System. The first was to perform in-depth testing of the System at the Company's facilities in Montreal, Canada; the second was to further automate the System.

This new Contract is aimed at enhancing the System’s reliability and performance, including upgrading several of its components. Once the upgrades are completed, the Company will perform specific long duration performance tests using surrogate material. During this period, PyroGenesis will also train specialized personnel to enable them to be able to perform final testing with live agents at the Client's facilities. Once the local testing and training is complete, the System will be refurbished, packaged, and sent abroad for live testing. The Client is planning to spend an additional US $100MM during this final testing phase of PyroGenesis’ System.

According to the Organization for the Prohibition of Chemical Weapons, 6,715 metric tonnes of declared chemical warfare agent (“CWA”), such as the ones used in Syria, still remain worldwide1. Many of these stockpiles are aging and are too dangerous to transport, making PyroGenesis’ Tactical Mobile Plasma System an ideal solution for this problem.

PyroGenesis has received total funding of approximately US $2MM (including this new Contract) to develop this technology. “What was merely an idea a few years ago,” said Pierre Carabin, Director of Engineering of PyroGenesis, “is now a full scale operating reality. We are looking forward to the further improvements and testing program of the System”.

Work on this new Contract is expected to be completed by Q1-2017.

“This Contract is a testament to the level of confidence the military has in our experience and expertise,” said P. Peter Pascali, President and CEO of PyroGenesis. “It further underscores our

1www.opcw.org

ability to perform to military standards which is serving us well as we expand into several other fast growing business segments.”

Separately, the Company announces today that Ms. Sophy Cesar, VP, Investor Relations and Communications, will no longer be employed by the Company as at September 21, 2016.

http://www.pyrogenesis.com/wp-content/uploads/2016/09/Signed…

News

PYROGENESIS ANNOUNCES SUCCESSFULLY DESTROYING SIMULATED CHEMICAL WARFARE AGENTS FOR THE US MILITARY; EXCEEDING 99.9999% DESTRUCTION EFFICIENCY. http://www.pyrogenesis.com/wp-content/uploads/2017/04/SUCCES…

MONTREAL, QUEBEC--(Marketwired – April 19, 2017) - PyroGenesis Canada Inc. (http://pyrogenesis.com) (TSX-V: PYR) (OTCQB: PYRNF), a high tech company (the “Company” or “PyroGenesis” or “PCI”) that designs, develops, manufactures and commercializes plasma based systems and plasma torch products, is pleased to announce today that, further to its press release of September 14, 2016, PyroGenesis has, in coordination with the US-based Southwest Research Institute (SwRI), successfully completed long-duration performance tests using the Company’s tactical Plasma Arc Chemical Warfare Agents Destruction System (“PACWADS” or the “System”) using surrogate chemical warfare agent material. These tests supported the Defense Advanced Research Projects Agency (DARPA) Agnostic Compact Demilitarization of Chemical Agents (ACDC) program and far exceeded minimum requirements with over 99.9999% destruction efficiency.

“DARPA’s mission is to make pivotal investments in breakthrough technologies, to affect transformational change instead of incremental advances. In the scope of this project, PyroGenesis’ System is the key to revolutionizing the mobile destruction of Chemical Warfare Agents (CWAs)”, said Jean-René Gagnon, Process Engineering Lead at PyroGenesis. “The Company is proud to be working with such a prestigious partner on such a challenging project.”

PyroGenesis’ PACWADS is a stand-alone thermal treatment device, with a liquid scrubber system. This mature technology is designed to be easily transported and deployed in a field setting, close to where threats may be found, to rapidly and safely destroy a wide range of chemical warfare agents. The System successfully underwent CWA simulant testing at the PyroGenesis facility in Montreal, Canada, in January and February of 2017. The System demonstrated greater than a 6-log reduction in CWA simulant and the effective scrubbing of acid gases.

Under the DARPA ACDC program, SwRI designed a scrubber system that neutralizes toxic CWA decomposition products and acid gases into non-hazardous components by safely incorporating these compounds into soil and changing their state. The system is a modular and mobile unit. After the chemicals are destroyed, exhaust gases are passed through a soil-based scrubber beds where the byproducts of combustion are captured and further baked using a novel soil-based pollution abatement system. The soil, after use, remains non-hazardous and useful.

In February 2017, the SwRI soil-based scrubber module was connected to the PyroGenesis PACWADS plasma combustion chamber exhaust and tested. CWA simulants were destroyed by the plasma torch in a series of tests emulating destruction of CWA agents sarin (GB), soman (GD), and mustard (HD). The two modules – plasma torch front end, and ACDC soil scrubber back end – demonstrated a more than 99.9999% efficiency in CWA simulant reduction and the effective scrubbing of acid gases within a soil medium.

“If successful, PACWADS will be one of the few technologies in the world certified to destroy CWAs. PyroGenesis anticipates that receiving this certification will open the door to additional opportunities,

such as the safe destruction of Ebola contaminated material, just to name one”, said Philippe Beaulieu, Senior Project Manager at PyroGenesis.

“A successfully developed system would safely destroy chemical warfare agent stockpiles onsite without having to transport these highly toxic chemicals to a remote location for processing,” said P. Peter Pascali, President and CEO of PyroGenesis. “Successfully completing this contract reflects the significant advances that we, at PyroGenesis, have achieved, and which we expect to continue to achieve in the area of defense and chemical warfare agent destruction. This, coupled with the fact that our plasma based waste destruction system is specified in the design of the new generation US aircraft carrier, with two systems already having been delivered, further solidifies our position within the US military as being the ‘go-to’ supplier of plasma-based solutions.”

Separately, PyroGenesis announces today that a series of warrants previously issued by the Company has been fully exercised. The warrants were issued in connection with a private placement offering completed on November 26, 2014, which terms were subsequently amended to effectively reduce the exercise price from $0.55 to $0.195, and to extend the expiration date from November 26, 2016 to November 26, 2017. As a result of such exercise, the Company received an aggregate amount of $417,857.12, and issued 2,142,857 common shares in its share capital.

PyroGenesis is also pleased to announce that it recently became a member of the 8020 Connect community. 8020 Connect (www.8020connect.com) is the investment industry's newest social investor network, developed to deliver corporate information to shareholders, investment industry experts and like-minded investors, while enabling these group members to interact with one another and with the company's corporate management team.

Through the 8020 Connect shareholder and investor network, PyroGenesis can communicate its corporate message and update advancements and financial information to all shareholders and investors in a timely and effective fashion. The 8020 Connect social media component provides direct interaction with shareholders, allowing the company to respond to questions and inquiries directly or through our private investor group forums. The 8020 Connect network will also allow PyroGenesis to expand its audience to interested investors and industry experts worldwide.

Video Plasma Waste-to-Energy System - PyroGenesis

Beobachte die schon länger, aber was die können, kann ich mit Sachen aus dem Baumarkt für 200Euro genauso gut, soll sogar bei Radioaktivität funktionieren - ich bin halt nur nicht börsennotiert Das Ding nennt sich Drycell, "Brille" mal danach

Das Ding nennt sich Drycell, "Brille" mal danach , der Plasmastrahl, der da rauskommt, ist 6000Grad heiss und kann fats alles schmelzen/transmutieren. Ich ahnte schon immer, dass gewisse Technologien, die relativ einfach konzipiert sind, unten gehalten werden, damit die Wirtschaft und das todesopfernde Rad am Laufen gehalten werden.

, der Plasmastrahl, der da rauskommt, ist 6000Grad heiss und kann fats alles schmelzen/transmutieren. Ich ahnte schon immer, dass gewisse Technologien, die relativ einfach konzipiert sind, unten gehalten werden, damit die Wirtschaft und das todesopfernde Rad am Laufen gehalten werden.

Das Ding nennt sich Drycell, "Brille" mal danach

Das Ding nennt sich Drycell, "Brille" mal danach , der Plasmastrahl, der da rauskommt, ist 6000Grad heiss und kann fats alles schmelzen/transmutieren. Ich ahnte schon immer, dass gewisse Technologien, die relativ einfach konzipiert sind, unten gehalten werden, damit die Wirtschaft und das todesopfernde Rad am Laufen gehalten werden.

, der Plasmastrahl, der da rauskommt, ist 6000Grad heiss und kann fats alles schmelzen/transmutieren. Ich ahnte schon immer, dass gewisse Technologien, die relativ einfach konzipiert sind, unten gehalten werden, damit die Wirtschaft und das todesopfernde Rad am Laufen gehalten werden.

Antwort auf Beitrag Nr.: 54.794.065 von H2OAllergiker am 24.04.17 20:17:55Schade solltest Du mal an die Börse gehen melde Dich

Das Technologien bewusst zurückgehalten werden war schon immer so und wird wohl auch so bleiben

Ich habe mich eher wegen dem Pulver für das 3D drucken entschieden hier einzusteigen, aber ich nehme auch gerne die andern Entwicklung mit, kann ja nicht so schlecht sein, wenn der Kurs steigt.

Das Technologien bewusst zurückgehalten werden war schon immer so und wird wohl auch so bleiben

Ich habe mich eher wegen dem Pulver für das 3D drucken entschieden hier einzusteigen, aber ich nehme auch gerne die andern Entwicklung mit, kann ja nicht so schlecht sein, wenn der Kurs steigt.

PYR halte ich für eine der innovativsten Techaktien, die ich kenne

ich schick dir ne BM, falls Du handwerklich begabt und technisch nicht unbegabt bist,

PyroGenesis Announces First Order for 3D Printing Powders

Darauf habe ich gewartet und jetzt noch keine Zeit die News richtig zu lesen

http://www.pyrogenesis.com/wp-content/uploads/2017/04/First-…

PyroGenesis Announces First Order for 3D Printing Powders from a Multinational Conglomerate; Down Payment Received; Interest exceeds Expectations

MONTREAL, QUEBEC--(Marketwired – April 25, 2017) - PyroGenesis Canada Inc. (http://pyrogenesis.com) (TSX-V: PYR) (OTCQB: PYRNF), a high-tech company (the “Company” or “PyroGenesis”) that designs, develops, manufactures and commercializes plasma waste-to-energy systems and plasma torch products, is pleased to announce today that, further to its press release dated March 30, 2017, it has signed its first contract, and received the down payment, for an order of titanium powder (Ti-6Al-4V) and Inconel from a multinational conglomerate (the “Client”), the name and origin of which will not be disclosed for competitive reasons. Note, this order was placed during the ramp-up phase of the Company’s powder production system (the “System”).

“As previously announced on March 30, 2017, we did not expect this type of interest before ramp-up was complete, and we would have considered any sample orders (i.e. up to 500kg) made before such time to be very significant as this further validates our strategic decision to enter into powder production,” said P. Peter Pascali, President and CEO of PyroGenesis. “This order is a sample order and is most significant in terms of timing and who the Client is, rather than the dollar value itself. The fact that a multinational conglomerate has taken the time to sample our powders before the ramp-up phase is complete is extremely noteworthy. We believe that the contract announced today is just one of many to come. We are very pleased with these developments which we believe underscore the interest in the marketplace for PyroGenesis’ products and unique expertise.”

PyroGenesis’ System uses Plasma Atomization to make small, uniform, fully dense and spherical metal powders that flow like water, and which are highly sought after in the Additive Manufacturing (“AM”) industry.

PyroGenesis is the inventor of Plasma Atomization. The Company first began producing powders using this technology for the biomedical industry between 2001-2004. In 2015, PyroGenesis invested approximately $2MM in improving both the production rate and particle size distribution, which not only led to a patent pending, but also to PyroGenesis’ decision to re-enter the market and produce powders for the AM industry. The System is the first of many PyroGenesis expects to make to address an increasing need for metal powders in the AM industry.1

Additionally, PyroGenesis announces today that it has signed a number of agreements with significant and potential players in the AM industry, wherein the Company is in discussions

regarding the possibility of concluding certain business relationships or transactions related to AM, most notably geared to the production of powders.

“These are very exciting times for PyroGenesis,” said Mr. Pascali. “These events seem to further validate our decision to enter the additive manufacturing industry, and although noteworthy, we caution concluding that anything of significance will happen quickly. Discussions take time and we are still in the early phases.”

“The ramp-up phase will continue through the remainder of the second quarter of 2017, of which we note that the operational performance and progress to date far exceed our expectations,” said Pierre Carabin, Chief Technology Officer of PyroGenesis. “Our team remains focused and dedicated to our commitments to deliver high quality powders to the additive manufacturing industry, while continuing to innovate and improve our process which is arguably, already, the gold standard for the industry.”

Finally, as previously announced, the metal powders produced during the ramp-up phase are available for sale. The initial focus is on producing commercially pure Titanium (CP Ti) and Ti-6Al4V powders; however PyroGenesis is receiving interest for other metal powders as well which it is also attending to.

PyroGenesis’ System uses Plasma Atomization to make small, uniform, fully dense and spherical metal powders that flow like water, and which are highly sought after in the Additive Manufacturing (“AM”) industry.

PyroGenesis’ System uses Plasma Atomization to make small, uniform, fully dense and spherical metal powders that flow like water, and which are highly sought after in the Additive Manufacturing (“AM”) industry.

Das haut rein, bester Performer zur Zeit, Rückschlagsgefahr steigt nun täglich, muss mal auf die Kerzen schauen.

Wenn wir zum Freitag nicht deutlich über 0,84 schliessen, wars das erstmal für ne lange Zeit - ohne News tut sich da dann erstmal garnichts mehr, denke ich:

Dieses Bild ist nicht SSL-verschlüsselt: [url]http://bigcharts.marketwatch.com/kaavio.Webhost/charts/big.chart?nosettings=1&symb=CA%3aPYR&uf=0&type=4&size=2&sid=7451634&style=320&freq=1&entitlementtoken=0c33378313484ba9b46b8e24ded87dd6&time=11&rand=839227188&compidx=aaaaa%3a0&ma=0&maval=9&lf=1&lf2=0&lf3=0&height=335&width=579&mocktick=1

[/url]

Antwort auf Beitrag Nr.: 54.813.688 von H2OAllergiker am 26.04.17 20:23:13Auch mein Bester Performer

Die Schwankungsbreite ist allerdings sehr groß, hatte ja mal kurz überlegt nochmal nachzufassen, das lass ich jetzt erstmal.

Hatte letztes Jahr mal Nexoptic auf meine Beobachtungliste genommen, aber nie gekauft, die sind von 0,40 auf über 3 gestiegen und pendeln im Moment um 2, also auf PyroGenesis - Träumen wird ja erlaubt sein

Aber ehrlich ich weiß nicht ob meine Nerven das mitmachen würden

Die Schwankungsbreite ist allerdings sehr groß, hatte ja mal kurz überlegt nochmal nachzufassen, das lass ich jetzt erstmal.

Hatte letztes Jahr mal Nexoptic auf meine Beobachtungliste genommen, aber nie gekauft, die sind von 0,40 auf über 3 gestiegen und pendeln im Moment um 2, also auf PyroGenesis - Träumen wird ja erlaubt sein

Aber ehrlich ich weiß nicht ob meine Nerven das mitmachen würden

Video: Robert McWhirter discusses Pyrogenesis Canada

http://www.bnn.ca/video/robert-mcwhirter-discusses-pyrogenes…Ich bekomme es leider nicht abgespielt, liegt eventuell an meinem Browswer

Wie bist Du auf Nexoptic gekommen, gabs da Werbung oder soetwas? Beobachte die auch, Ende April soll doch da etwas entscheidendes kommen, ich vermute, es wird für den Kurs eher negativ werden. Bei ariva meint jemand, die NXO Technologie sei mit Linsentechnik nicht erklärbar, eher mit einer von der Stanford entwickelten Technologie, die im Microbereich den Lichteinfall manipuliert/umlenkt, ich denke da jetzt konkret an Quantumdots/ops (oder so ähnlich?), hat wahrscheinlich u.a. etwas mit einem Tarnanzug zu tun, der Licht umlenkt, anscheinend arbeiten die Militärs im Einsatz schon damit, nahezu Unsichtbarkeit fürs menschliche Auge via Tarnuniform.

Metamaterialien/ "Quantum Stealth" meinte ich: http://www.focus.de/wissen/technik/erfindungen/revolutionaer… http://www.trendsderzukunft.de/hyperstealth-quantum-material…

Antwort auf Beitrag Nr.: 54.814.738 von H2OAllergiker am 26.04.17 22:14:59Kann ich Dir gar nicht mehr so genau sagen, könnte eine News auf Stockhouse gewesen sein.

Pyrogenesis announces 2016 results

PyroGenesis Announces 2016 Results: Revenues Decrease 16%; Gross Margins (before non-cash items) Increase to 41%; EBITDA (Adj.) Improves 33% Year Over Year; Current Backlog $9.9MMV.PYR |

http://www.stockhouse.com/news/press-releases/2017/04/28/pyr…

PyroGenesis Announces 2016 Results: Revenues Decrease 16%; Gross Margins (before non-cash items) Increase to 41%; EBITDA (Adj.) Improves 33% Year Over Year; Current Backlog $9.9MM

MONTREAL, QUEBEC--(Marketwired - April 28, 2017) - PyroGenesis Canada Inc. (http://pyrogenesis.com) (TSX VENTURE:PYR) (OTCQB:PYRNF), a high-tech company (the "Company" or "PyroGenesis") that designs, develops, manufactures and commercializes plasma waste-to-energy systems and plasma torch products, is pleased to announce today its financial and operational results for the fourth quarter and the fiscal year ended December 31, 2016.

"Despite a decrease of 16% in revenues, and non-cash write-offs totaling $2.8MM, we believe we have had a challenging but stellar year in 2016, and have positioned the Company well for the coming years," said P. Peter Pascali, President and CEO of PyroGenesis. "2016 was a pivotal year for PyroGenesis as the Company shifted its focus away from being a fabricator of plasma- based systems that produced unique titanium powders, in favour of becoming a producer of such powders for the Additive Manufacturing Industry. This strategic decision resulted, in early 2016, in the termination of a $12.5MM contract to deliver ten (10) powder production systems to a client in Asia, which understandably put significant pressure on cash flows. This was further exacerbated by the need to secure funds to build the first powder production unit. Notwithstanding these challenges, the Company, in 2016, not only successfully managed the cash flow demands but has built its first powder production unit while at the same time improving Gross Margins (after non-cash items) to 41% (2015:27.1%), reducing EBITDA (Adj) loss year over year and ending the year with a healthy backlog of signed contracts of $9.9MM (2016 revenues: $5.2MM; 2015 revenues: $6.2MM), none of which are attributable to Additive Manufacturing."

Highlights

2016 was a year in which PyroGenesis posted:

A decrease of 16% in Revenues to $5,222,133 year over year;

An increase in Gross margins (before amortization of intangible assets and write-offs of inventories and costs and profits in excess of billings on uncompleted contracts) to 41.6%. (2015: 27.1%);

EBITDA loss of $4.9MM (including 2.8MM of write-offs);

Adjusted EBITDA loss of $1.7MM in Q4, 2016 (an improvement of 33% year over year);

A backlog of $9.9MM at December 31, 2016.

Outlook

2016 has been a pivotal year for PyroGenesis as the Company shifted its focus away from being a fabricator of plasma-based systems that produced unique titanium powders, in favour of becoming a producer of such powders for the Additive Manufacturing Industry. These powders are greatly sought after by the Additive Manufacturing industry given their unique properties which include pure, small, spherical, and uniform, allowing them to flow like water; a characteristic that is extremely important in industries such as 3D printing.

This strategic decision, made in early 2016, combined with the termination of the $12.5MM contract to deliver 10 powder production systems to a client in Asia, put significant pressure on cash flows, which was further exacerbated by the need to secure funds to build our first production unit. We are happy to announce that we have been successful on both fronts.

Removing the effect of the onetime non-cash write-offs of $2.8MM reveals the following results for 2016.

Gross Margin increased from 27% in 2015 to over 41% in 2016 despite a decrease in Revenues by 16% to $5.2MM in 2016 over 2015;

Adjusted EBITDA loss decreased from ($2.6MM) in 2015 to ($1.7MM) in 2016;

Over $13.5MM in contracts were signed, and work begun on, since June 30, 2016 which, taken in context of historic revenues (2016: $5.2MM; 2015: $6.2MM; 2014: $5.8MM) is quite significant. A significant portion of these contracts are expected to run through the financials in 2017. None of these revenues reflect any contracts for the sale of powders.

As previously mentioned, 2017 looks like a breakout year for a number of reasons, including:

The healthy gross margin (before consideration of the 2016 write-offs) established in 2016 is not only expected to continue into the foreseeable future, but improve once powder production is in full swing.

Established backlog of signed contracts, the majority of which are expected to be completed in 2017.

Our traditional lines of business are poised to contribute significantly to the bottom line, namely:

Powder Production: The Company has met every milestone announced on the road to making metal powders for the Additive Manufacturing ("AM") Industry. It was recently announced that the assembly of the first powder production system was completed and that the first powder run exceeded expectations. The ramp up is under way and is expected to take place linearly over approximately four (4) months of which we are currently 25% complete. As announced in recent press releases interest has far exceeded Managements' expectations and an initial contract was signed for a sample amount of powder. Also recently announced was the fact that the Company has signed a number of agreements with significant and potential players in the AM industry reflecting various discussions regarding the possibility of concluding certain business relationships or transactions geared to the production of powders. This bodes well for 2017. The current system is the first of many PyroGenesis expects to make to address an increasing need for metal powders in the AM industry.1

DROSRITE™: The DROSRITE™ Furnace System was proven out at a North American customer's Mexican facility during the first half of 2016. Soon thereafter, a successful demonstration of the DROSRITE™ System in the Middle East took place, following which an unsolicited request to exclusively market the process in the region was received and is currently being discussed. Management's belief that the supply and installation of the first commercial sale in North America would enable the Company to leverage this success to generate a continued flow of orders for additional DROSRITE™ systems is being borne out. This recent flurry of activity and interest for the DROSRITE™ system bodes well for 2017 where we now expect to have at least 3 orders placed and delivered. We expect the first follow on contracts to be signed in the 2nd half of 2017. The market potential for PyroGenesis' DROSRITE™ system, from Aluminium dross alone, exceeds $400MM.

HPQ: On August 2, 2016 PyroGenesis announced that it had signed contracts totalling CDN $8,260,000 with HPQ Silicon Resources Inc., formally Uragold Bay Resources Inc. for the sale of IP and to provide a 200 metric tonne (MT) per year PUREVAP™ pilot system to produce silicon metal directly from quartz. This system will for the most part be constructed in 2017, with advancement of the contract accelerating in the second half of the year. According to percent completion accounting standards for revenue recognition the majority of these revenues will be recognized in the 2nd half of 2017. Of note, if successful, PyroGenesis benefits from a 10% royalty on all revenues derived from the use of this system by HPQ, subject to annual minimums.

Chemical Warfare Destruction System: The Company recently announced that PyroGenesis has, in coordination with the US-based Southwest Research Institute (SwRI), successfully completed long-duration performance tests using the Company's tactical Plasma Arc Chemical Warfare Agents Destruction System ("PACWADS") using surrogate chemical warfare agent material. These tests supported the Defense Advanced Research Projects Agency (DARPA) Agnostic Compact Demilitarization of Chemical Agents (ACDC) program and far exceeded minimum requirements with over 99.9999% destruction efficiency. The PACWADS is now scheduled to go through final testing using real chemical warfare agents by the US Military). These tests should be completed by the end of Q3 2017 (this timeline, however is out of the Company's control). Again this bodes well for 2017 as we would expect additional contracts resulting from a successful completion of the final testing. However, no indication has been given as to the size, if any, such procurement would entail.

Other Contracts: There are other contracts being discussed (such as a third order for a PAWDS for a New US Aircraft Carrier which is expected to be ordered sometime towards the end of 2017/beginning of 2018 with an estimated value of approximately $6MM; SPARC system sales, amongst others) which give us confidence that overall 2017 looks like a break out year.

1 Wohlers Report 2016 (ISBN 978-0-9913332-2-6)

These points are strongly indicative of a strong performance in the coming year, and based on existing contracts, the Company expects to be profitable in 2017 excluding any contribution from powder sales as noted above. Further underscoring the sentiment for 2017, is how our entrance as a powder producer has been so well received by the Additive Manufacturing community.

Management remains focused on reducing PyroGenesis' dependency on long-cycle projects by developing a strategic portfolio of volume driven, high margin/low risk products that resolve specific problems within niche markets, and doing so by introducing these plasma-based technologies to industries that have yet to consider such solutions.

Management is also actively targeting recurring revenue opportunities that will generate a growing, and profitable, regular cash flow to the Company.

PyroGenesis has one of the largest concentrations of plasma expertise in the world, with over 250 years of accumulated technical experience and 59 patents, combined with unique relationships with major Universities performing cutting edge plasma research and development, which positions the Company well to execute this strategy.

All indications are that 2017 will be a breakout year for more than one of the Company's product lines. The Company's focus will continue to be to generate an improved mix of short and long term projects that will, in turn, facilitate operational and financial planning. Repeat orders for the same, or similar, products will further result in the standardization of manufacturing processes which will lead to improved gross margins.

Financial Summary

Revenues

The Company posted revenues of $1,483,543 in the fourth quarter of 2016 ("Q4, 2016"), representing a decrease of 33% compared with $2,228,272 recorded in the fourth quarter of 2015 ("Q4, 2015"). Revenue recorded in Fiscal 2016 was generated primarily from (i) the sale of intellectual property and development of a vacuum arc reducing process to convert Silica into high purity Silicon metal, (ii) manufacture and further field testing of Tactical PACWADS, the first mobile plasma system for destruction of chemical warfare agents under contract with an international military consortium, (iii) the demonstration of the viability of PyroGenesis' existing plasma chemical warfare agent destruction platform with locally available materials, for the complete eradication of chemical warfare agents without creating hazardous by-products, (iv) support services related to PAWDS-Marine systems supplied to the US Navy and (v) to manufacture and deliver a fully automated plasma torch system comprised of six air plasma torches to be used for waste gasification.

Cost of Sales and Services and Gross Margins

Cost of sales and services before amortization of intangible assets and write-offs of inventories and costs and profits in excess of billings on uncompleted contracts was $3,051,356 in 2016, representing a decrease of 33% compared with $4,551,090 in 2015. In the fourth quarter of 2016, the cost of sales and services before amortization of intangible assets and write-offs of inventories and costs and profits in excess of billings on uncompleted contracts was $901,072 representing a decrease of 41% compared with $1,538,828 in Q4, 2015.

Various factors, including, but not limited to a write-off of inventories and costs and profits in excess of billings on uncompleted contracts, the mix of long and short-term manufacturing projects, project complexity and scale, and project R&D content, may significantly impact both the composition and overall level of cost of sales and services reported in a given period, as the mix of labor, materials and equipment may be significantly different.

The costs incurred in 2016 are primarily attributable to managements decision to write-off inventories and costs and profits in excess of billings on uncompleted contracts, the work completed under PyroGenesis' project to develop a vacuum arc reducing process to convert Silica into high purity Silicon metal, together with work completed on the final, phase to design, manufacture and deliver a fully automated plasma torch system comprised of six air plasma torches to be used for waste gasification, work completed on the tactical mobile plasma system for destruction of chemical warfare agents under contract with an international military consortium, and support services related to PAWDS Marine systems supplied to the US Navy.

Investment tax credits recorded against cost of sales are primarily related to client funded projects that qualify for tax credits from the provincial government of Quebec. Qualifying tax credits decreased to $249,550 in 2016, compared with $544,676 in 2015, this is primarily due to the Company having adjusted the 2016 qualifying tax credits to incorporate amounts disallowed for the 2015 qualifying tax credits. This represents a decrease of 54% year-over-year. The Company continues to make investments in research and development projects incorporating the involvement of strategic partners and government bodies.

In 2016, the gross margin before amortization of intangible assets and write-offs of inventories and costs and profits in excess of billings on uncompleted contracts was $2,170,777, which represents 41.6% of revenue. This compares with a gross margin before amortization of intangible assets of $1,690,913 (27.1% of revenue) for 2015.

The amortization of intangible assets of $1,396,675 in 2016 ($1,397,074 in 2015) relates to the licenses and know-how purchased in 2011 from a company under common control. This expense is a non-cash item and the underlying asset is fully amortized by December 31, 2016.

Selling, General and Administrative Expenses

Selling, general and administrative expenses ("SG&A") for 2016 were $4,320,862, representing a decrease of 7% compared with $4,648,473 reported for 2015. Excluding the costs associated with share-based compensation (a non-cash item in which options vest over a four year period), SG&A expenses decreased by 8% in 2016 compared with 2015.

The decrease in SG&A expenses is attributable to the net effect of (i) an increase of 1% in employee compensation, (ii) a decrease of 18% for professional fees, primarily due to lower accounting fees, (iii) a decrease of 10% in office and general costs, primarily due lower communication expenses, (iv) travel costs decreased by 20%, due to less travel abroad, (v) depreciation on property and equipment decreased by 22% due to a reduced level of investments in machinery and equipment since 2010, when major acquisitions were made, (vi) government grants decreased by 41% due to lower level of activities supported by such grants, (vii) other expenses decreased by 34%, primarily due to the reduced cost of freight and shipping costs and (viii) an increase in share base payments of 12% primarily due to the vesting structure of the stock option plan and the stock options offered on September 25, 2016.

Separately, share based payments increased by 12% as a result of the vesting structure of the stock option plan and for new options issued in 2016.

Total Comprehensive Loss

The comprehensive loss for 2016 was $6,952,219 compared to a loss of $4,917,779 in 2015, representing an increase of 41% year-over-year.

The increase of $2,034,440 in the comprehensive loss in 2016 is primarily attributable to: (i) a decrease in product and service related revenue of $1,019,871 arising in 2016, (ii) a decrease in cost of sales and services totaling $1,500,134, primarily due to the concentration of engineering on developing the 3D printing powder production system, (iii) a decrease in SG&A expenses of $327,611 arising in 2016 primarily due to a decrease in professional fees, (iv) a decrease in R&D expenses of $44,625 primarily due to the fact that some of the R&D expenses were capitalized, (v) an increase in net finance costs of $132,501 that is primarily due to interest on the convertible debenture and the tax credit loans obtained in 2016, (vi) an increase of $2,754,438 for the write- off of inventories and costs and profits in excess of billings on uncompleted contracts.

EBITDA

The EBITDA loss in 2016 was $4,869,297 compared with an EBITDA loss of $2,930,637 for 2015, representing an increase of 66%. The increase in the EBITDA loss in 2016 compared with 2015 includes amounts written-off of $2,754,438.

Adjusted EBITDA loss in 2016 was $1,748,834 compared with an Adjusted EBITDA loss of $2,602,987 for 2015. The decrease of $854,153 in the Adjusted EBITDA loss in 2016 is attributable to the increased comprehensive loss of $2,034,440, a decrease of $36,322 in depreciation on property and equipment, a decrease of $399 in amortization of intangible assets, an increase in finance charges of $132,501, an increase in cost of other non-cash items, specifically share-based payments of $38,375 an increase in write-off of inventories of $994,015 and an increase in write-off of costs and profits in excess of billings on uncompleted contracts of $1,760,423.

Liquidity

As at December 31, 2016, the Company had cash on hand of $385,257 and a negative working capital of $2,079,353 compared with a cash balance of $767,368 and positive working capital of $166,095 as at December 31, 2015.

About PyroGenesis Canada Inc.

PyroGenesis Announces Contract for Second Phase Lab Scale Testing Program

https://filecrypt.cc/Container/BCEEC9F500.htmlPyroGenesis Announces Contract for Second Phase Lab Scale Testing Program Totalling CAN$170,000 with HPQ Silicon Resources Inc.

MONTREAL, QUEBEC--(Marketwired – May 4, 2017) - PyroGenesis Canada Inc. (http://pyrogenesis.com) (TSX-V: PYR) (OTCQB: PYRNF), a high-tech company (the “Company” or “PyroGenesis”) that designs, develops, manufactures and commercializes plasma waste-toenergy systems and plasma torch products, is pleased to announce today that it has signed a contract for CAN$170,000 with HPQ Silicon Resources Inc. (“HPQ”), wherein PyroGenesis will provide a second phase of Process Characterization Testing (the “Testing”), using a newly upgraded version of the lab scale PUREVAP™ Quartz Reduction Reactor (the “Reactor”).

The purpose of the Testing is to build upon the bench scale success made to date and to push the design of the lab scale Reactor to a point that will allow it to operate in a semi-batch mode to produce silicon (Si) samples. The Testing will use higher purity feedstock (99.5% SiO2.) with a goal of producing at least 5N (99.999% Si) Solar Grade Silicon Metal at lab scale.

This Testing program will take place over the next several months, and will be in conjunction with the delivery of the pilot plant Reactor scheduled for October 2017. The objectives of these metallurgical tests will be, amongst others, to: (i) generate and collect data that can be used for the scale-up of the lab scale Reactor and ultimately, for the commercial scale-up of the PUREVAP™ process; and (ii) to continue testing different purification alternatives.

PyroGenesis will provide HPQ with samples for third party independent purity validation as well as a milestones report and final report summarizing the results and analysis.

“We are eager to start this additional testing phase,” said Pierre Carabin, Chief Technology Officer of PyroGenesis. “This new testing will allow us to validate the design of pilot plant Reactor and to further improve the product purity.”

“The further we proceed in this project, the more confident we are that we have found a plasma-based application that can be applied to quartz in a commercial setting,” said P. Peter Pascali, President and CEO of PyroGenesis. “We are very pleased with the results to date. That is not to say we have succeeded, will succeed, or that there won’t be challenges ahead. To the contrary, we fully expect there will be challenges as in any project; however we are certain that we will meet those challenges as we have with other projects, and find the best possible solution, if any. Once again, we are extremely pleased with the success of the project to date and the results that we have achieved.”

PyroGenesis Announces Q1 2017 Results

http://www.pyrogenesis.com/wp-content/uploads/2017/05/Q1-201…PyroGenesis Announces Q1 2017 Results: Cash Flow Positive on EBITDA (Adj.) Basis; Revenues Increase 67%; Gross Margins Increase to 52%; Current Backlog $9.4MM. MONTREAL, QUEBEC--(Marketwired – May 30, 2017) - PyroGenesis Canada Inc. (http://pyrogenesis.com) (TSX-V: PYR) (OTCQB: PYRNF), a high-tech company (the “Company” or “PyroGenesis”) that designs, develops, manufactures and commercializes plasma waste-toenergy systems and plasma torch products, is pleased to announce today its financial and operational results for the first quarter ended March 31, 2017.

Q1 2017 results reflected the following highlights:

• Revenues increased 67% to $1.7MM in Q1 2017 from $1.0 MM posted in Q1 2016;

• Gross profit after amortization of intangible assets increased to 52% in Q1 2017, from 5.5% over the same period in 2016. (Gross profit before amortization of intangible assets increased to 52% in Q1 2017 from 29% over the same period in 2016);

• Most importantly, Q1 2017 was profitable on an EBITDA (adjusted) basis. Q1 2017 posted an EBITDA (adj.) of $22.6K versus a EBITA (adj.) loss of $649.5K;

• Over $13.5MM in contracts were signed, and work begun on, since June 30, 2016 which, taken in context of historic revenues (2016: $5.2MM; 2015: $6.2MM; 2014: $5.8MM) is quite significant. Backlog of signed contracts as of the date of this writing is $9.4MM;

• Cash on hand at March 31st 2017 was $1.3 MM (December 31st 2016: $385K).

At year end 2016, we described the preceding twelve months as being a pivotal year for PyroGenesis as the Company shifted its focus away from being a fabricator of plasma-based systems that produced unique titanium powders, in favour of becoming a producer of metal powders for the Additive Manufacturing Industry (the “Industry”). Given their unique properties (pure, small, spherical, and uniform; which make them flow like water), these powders are greatly sought after in the Industry, particularly 3D printing. Given this strategic shift, together with the backlog of signed contracts from our non-additive manufacturing business (“Core/Traditional Lines of Business”) of over $13MM since June 30, 2016, we projected that 2017 was shaping up to be a break out year for PyroGenesis, and Q1 2017 has not disappointed.

The Company will be issuing an in depth update on the progress of its Powder Production business line within the next two weeks where a review will take place on all aspects of that

sector. Suffice it to say at this point that there have been no disappointments and we are very happy with the progress and developments to date.

What is key to note is that these results reflect revenues from what we call our Core/Traditional Lines of Business (ie no revenues from powder sales at all), however expenses reflect certain costs of building our first powder production system which came on stream in Q1 2017 and is, as previously announced, currently ramping up to full production.

We are more convinced than ever before that 2017 is the breakout year we have been positioning the Company for, for a number of reasons:

• The healthy gross margins established in 2016 (before consideration of the 2016 writeoffs), have improved, and are expected to continue to improve once powder production is in full swing; • Established backlog of signed contracts, the majority of which are expected to be completed in 2017; • Our Core/Traditional Lines of Business are poised to contribute significantly to the bottom line and be both profitable and significant in their own right.

The following is a non-exhaustive review of PyroGenesis’ main commercial activities:

A) Powder Production: The Company has met every milestone announced on the road to making metal powders for the Industry. It was recently announced that the assembly of the first powder production system was completed and that the first powder run exceeded expectations. The ramp up is under way and is expected to take place linearly over the ensuing months. As announced in recent press releases interest has far exceeded Managements’ expectations and an initial contract was signed for a sample amount of powder. Also recently announced was the fact that the Company has signed a number of agreements with significant and potential players in the Industry reflecting various discussions regarding the possibility of concluding certain business relationships or transactions geared to the production of powders. The current system is the first of many PyroGenesis expects to make to address an increasing need for metal powders in the Industry1.

B) DROSRITE™: The DROSRITE™ Furnace System was proven out at a North American customer’s Mexican facility during the first half of 2016. Soon thereafter, a successful demonstration of the DROSRITE™ System in the Middle East took place, following which an unsolicited request to exclusively market the process in the region was received and is currently being discussed. Management’s belief that the supply and installation of the first commercial sale in North America would enable the Company to leverage this success to generate a continued flow of orders for additional DROSRITE™ systems is being borne out.

1 Wohlers Report 2016 (ISBN 978-0-9913332-2-6)

This recent flurry of activity and interest for the DROSRITE™ system bodes well for 2017 where we now expect to have at least 3 orders placed. We continue to expect the first follow on contracts to be signed in the 2nd half of 2017. The market potential for PyroGenesis’ DROSRITE™ system, from Aluminium dross alone, exceeds $400MM.

C) HPQ: On August 2, 2016 PyroGenesis announced that it had signed contracts totalling CDN $8,260,000 with HPQ Silicon Resources Inc., formally Uragold Bay Resources Inc. for the sale of IP and to provide a 200 metric tonne (MT) per year PUREVAPTM pilot system to produce silicon metal directly from quartz. This system will for the most part be constructed in 2017, with advancement of the contract accelerating in the second half of the year. According to percent completion accounting standards for revenue recognition the majority of these revenues will be recognized in the 2nd half of 2017. Of note, if successful, PyroGenesis benefits from a 10% royalty on all revenues derived from the use of this system by HPQ, subject to annual minimums.

D) Chemical Warfare Destruction System: The Company recently announced that PyroGenesis has, in coordination with the US-based Southwest Research Institute (SwRI), successfully completed long-duration performance tests using the Company’s tactical Plasma Arc Chemical Warfare Agents Destruction System (“PACWADS”) using surrogate chemical warfare agent material. These tests supported the Defense Advanced Research Projects Agency (DARPA) Agnostic Compact Demilitarization of Chemical Agents (ACDC) program and far exceeded minimum requirements with over 99.9999% destruction efficiency. The PACWADS has, as of this writing, been delivered to the testing site and is currently going through final testing using real chemical warfare agents. These tests should be completed by the end of Q3 2017 (this timeline however is out of the Company’s control). Again this bodes well for 2017 as we would expect additional contracts resulting from a successful completion of the final testing. However, no indication has been given as to the size, if any, such procurement would entail.

E) Other Contracts: There are other contracts being discussed (such as a third order for a PAWDS for a New US Aircraft Carrier which is expected to be ordered sometime towards the end of 2017/beginning of 2018 with an estimated value of approximately $6MM; SPARC system sales, amongst others) which give us confidence that 2017 will be the break out year.

Given the above, we expect a strong performance in the coming year, and based on existing contracts, the Company expects to be profitable in 2017 (excluding any contribution from powder sales) as noted above. Our projections for 2017 are only heightened by the reception we have received so far and how our entrance as a powder producer has been so well received by the Additive Manufacturing community.

Management remains focused on reducing PyroGenesis’ dependency on long-cycle projects by developing a strategic portfolio of volume driven, high margin/low risk products that resolve

specific problems within niche markets, and doing so by introducing these plasma-based technologies to industries that have yet to consider such solutions.

Management is also actively targeting recurring revenue opportunities that will generate a growing, and profitable, regular cash flow to the Company.

PyroGenesis has one of the largest concentrations of plasma expertise in the world, with over 250 years of accumulated technical experience and 59 patents, combined with unique relationships with major Universities performing cutting edge plasma research and development, which positions the Company well to execute upon its various strategies.

Financial Summary

Revenues

The Company posted revenues of $1,696,138 in the first quarter of 2017 (“Q1, 2017”), representing an increase of 67% compared with $1,016,853 recorded in the first quarter of 2016 (“Q1, 2016”). Revenue recorded in Fiscal 2016 was generated primarily from (i) the sale of intellectual property and development of a vacuum arc reducing process to convert Silica into high purity Silicon metal, (ii) manufacture and further field testing of Tactical PACWADS, the first mobile plasma system for destruction of chemical warfare agents under contract with an international military consortium, (iii) the demonstration of the viability of PyroGenesis’ existing plasma chemical warfare agent destruction platform with locally available materials, for the complete eradication of chemical warfare agents without creating hazardous by-products, and (iv) support services related to PAWDS-Marine systems supplied to the US Navy.

Cost of Sales and Services and Gross Margins

Cost of sales and services before amortization of intangible assets was $820,864 in Q1, 2017, representing an increase of 13% compared with $723,256 in Q1, 2016. Total costs of sales and services, was $820,264 representing a decrease of 24% compared with $1,072,524 in Q1, 2016.

Various factors, including, but not limited to, the mix of long and short-term manufacturing projects, project complexity and scale, and project R&D content, may significantly impact both the composition and overall level of cost of sales and services reported in a given period, as the mix of labor, materials and subcontracts may be significantly different.

The costs incurred in Q1, 2017 are primarily attributable to the work completed under PyroGenesis’ project to develop a vacuum arc reducing process to convert Silica into high purity Silicon metal, work completed on the tactical mobile plasma system for destruction of chemical warfare agents under contract with an international military consortium, and support services related to PAWDS Marine systems supplied to the US Navy.

Investment tax credits recorded against cost of sales are primarily related to client funded projects that qualify for tax credits from the provincial government of Quebec. Qualifying tax

credits increased to $132,246 in Q1, 2017, compared with $108,815 in Q1, 2016. This represents an increase of 22% quarter-over-quarter. The Company continues to make investments in research and development projects incorporating the involvement of strategic partners and government bodies.

In Q1, 2017, the gross margin before amortization of intangible assets was $875,874, which represents 51.6% of revenue. This compares with a gross margin before amortization of intangible assets of $293,597 (28.9% of revenue) for Q1, 2016.

The amortization of intangible assets of Nil in Q1, 2017 ($349,268 in Q1, 2016) relates to the licenses and know-how purchased in 2011 from a company under common control. This expense is a non-cash item and the underlying asset was fully amortized by December 31, 2016.

Selling, General and Administrative Expenses

Selling, general and administrative expenses (“SG&A”) for Q1, 2017 were $1,148,916, representing an increase of 10% compared with $1,048,915 reported for Q1, 2016. Excluding the costs associated with share-based compensation (a non-cash item in which options vest over a four year period), SG&A expenses increased by 3% in Q1, 2017 compared with Q1, 2016.

The increase in SG&A expenses is attributable to the net effect of (i) a decrease of 2% in employee compensation, (ii) an increase of 10% for professional fees, primarily due to increase in investor relations, (iii) a decrease of 1% in office and general expenses, due to a decrease in courses and seminars, (iv) travel costs increased by 6%, due to an increase in travel abroad, (v) depreciation on property and equipment decreased by 22%, (vi) government grants decreased by 100% due to lower level of activities supported by such grants, (vii) other expenses increased by 1%, primarily due to the reduced cost of freight and shipping, and (viii) an increase in share base payments of 12% primarily due to the vesting structure of the stock option plan and the stock options offered on September 25, 2016.

Total Comprehensive Loss

The comprehensive loss for Q1, 2017 was $298,610 compared to a loss of $1,248,661 in Q1, 2016, representing a decrease of 76% quarter-over-quarter.

The decrease of $950,051 in the comprehensive loss in Q1, 2017 is primarily attributable to: (i) an increase in product and service related revenue of $679,285, (ii) an increase in cost of sales and services totaling $97,009 as explained above, (iii) an increase in SG&A expenses of $100,002 as explained above, (iv) an increase in R&D expenses of $25,187 primarily due to the fact that many of the Company’s engineering and R&D resources were concentrated on activities within projects under construction for clients, with such costs being recorded within cost of sales, (v) an increase in net finance costs of $6,647 due to an increase in accretion costs on convertible debentures, (vi) an increase in finance income of $150,343 due to the adjustment of the fair market value of other investments.

EBITDA

The EBITDA loss in Q1, 2017 was $115,565 compared with an EBITDA loss of $715,937 for Q1, 2016, representing a decrease of 84%.

Adjusted EBITDA gain in Q1, 2017 was $22,586 compared with an Adjusted EBITDA loss of $649,506 for Q1, 2016. The increase of $672,092 in the Adjusted EBITDA in Q1, 2017 is mainly attributable to the decreased comprehensive loss of $950,051, a decrease in depreciation on property and equipment of $7,058, a decrease of $349,268 in amortization of intangible assets, offset by an increase in finance charges of 6,647 and an increase in share-based payments of $71,720.

Liquidity

As at March 31, 2017, the Company had cash on hand of $1,278,447 and negative working capital of $6,004,376 compared with a cash balance of $385,257 and negative working capital of $2,079,353 as at December 31, 2016.

Interview Darren Stewart, speaks with PyroGenesis CEO, Peter Pascali

PyroGenesis Announces Receipt of Second Order for 3D Printing Powders

http://www.pyrogenesis.com/wp-content/uploads/2017/06/PR-Sec…PyroGenesis Announces Receipt of Second Order for 3D Printing Powders During Ramp-Up Phase; Interest in Powders Continues to Increase

MONTREAL, QUEBEC--(Marketwired – June 7, 2017) - PyroGenesis Canada Inc. (http://pyrogenesis.com) (TSX-V: PYR) (OTCQB: PYRNF), a high-tech company (the “Company” or “PyroGenesis”) that designs, develops, manufactures and commercializes advanced plasma processes and plasma torch products, is pleased to announce today that it has signed its second contract for an order of titanium powder (Ti-6Al-4V) from a US based end user (the “Client”), the name and origin of which will not be disclosed for competitive reasons. Note, this is the second order placed during the ramp-up phase of the Company’s powder production system (the “System”), and exceeds the original expectations for powder sales during this phase.

PyroGenesis’ System uses Plasma Atomization to make small, uniform, fully dense and spherical metal powders that flow like water, and which are highly sought after in the additive manufacturing industry.

PyroGenesis is the inventor of Plasma Atomization. The Company first began producing powders using this technology for the biomedical industry between 2001-2004. In 2015, PyroGenesis invested approximately $2MM in improving both the production rate and particle size distribution, which not only led to a patent pending, but also to PyroGenesis’ decision to re-enter the market and produce powders for the AM industry. The System is the first of many PyroGenesis expects to make to address an increasing need for metal powders in the AM industry.1

“As previously announced on March 30, 2017, we did not expect this type of interest before ramp-up was complete, and we would have considered any sample orders (i.e. up to 500kg) made before such time to be very significant as this would further validate our strategic decision to enter into powder production,” said P. Peter Pascali, President and CEO of PyroGenesis. “Although this order is a sample order what is truly noteworthy is it’s the second order we have received during ramp up. The fact that this Client has taken the time to sample our powders and allocate the funds to qualifying it internally, all before the ramp-up phase is complete is extremely significant. The two sample orders received to date exceed our initial expectations for powder sales. We believe that a third sample order received during the ramp up phase would underscore the interest in the marketplace for PyroGenesis’ products and unique expertise.”

On March 30th, 2017, PyroGenesis announced that it had completed the assembly of its first powder production system, and that the first powder run exceeded expectations. The ramp-up that was already underway was expected to take place over the ensuing (4) months (April-July).

“We note that so far the operational performance and progress to date, during the ramp-up phase, far exceed our expectations,” said Pierre Carabin, Chief Technology Officer of PyroGenesis. “Our team remains focused and dedicated to our commitments to deliver high quality powders to the additive manufacturing industry, while continuing to innovate and improve our process which is arguably, already, the gold standard for the industry.”

“These continue to be very exciting times for PyroGenesis,” said Mr. Pascali. “This second order, and although noteworthy, we continue to be cautious from concluding that anything of significance will happen quickly. Discussions take time and we are still in the early phases. Suffice it to say at this point that there have been no disappointments and we continue to be happy with the progress and developments to date.”

The Company will be issuing an in depth update on the progress of its Powder Production business line within the next week where a review will take place on all aspects of that sector.

General Update on Additive Manufacturing

http://www.pyrogenesis.com/wp-content/uploads/2017/06/Creati…PyroGenesis Announces Creation of “PyroGenesis Additive”: Division Dedicated to Additive Manufacturing and First Step to Spin-off; Provides General Update on Additive Manufacturing

MONTREAL, QUEBEC--(Marketwired – June 14, 2017) - PyroGenesis Canada Inc. (http://pyrogenesis.com) (TSX-V: PYR) (OTCQB: PYRNF), a high-tech company (the “Company” or “PyroGenesis”) that designs, develops, manufactures and commercializes plasma waste-to-energy systems and plasma torch products, is pleased to announce today that it has created a new division under the name of “PyroGenesis Additive”, dedicated solely to PyroGenesis’ additive manufacturing business line. This is the first step to the Company’s previously announced strategic spin-off.

PyroGenesis is the inventor of Plasma Atomization, using this process to produce very small, uniform, fully dense and spherical metal powders that flow like water, and which are highly sought after in the additive manufacturing (“AM”) Industry.

The Company first began producing powders using Plasma Atomization for the biomedical industry between 2001-2004. In 2015, PyroGenesis invested approximately $2MM in improving both the production rate and particle size distribution, which led not only to a patent pending, but also to PyroGenesis’ decision to re-enter the market and produce powders for the AM Industry.

The following highlights and developments have been made to date:

• On October 26, 2015, PyroGenesis announced that it was re-entering the market to produce metal powders, specifically for AM (3D printing); • On April 7, 2016, PyroGenesis announced its intention to spin-off its additive manufacturing capabilities into an independent public entity; • On April 27, 2016, PyroGenesis announced that its 3D metal particle size distribution greatly exceeded expectations; • On October 25, 2016, PyroGenesis announced that it had filed a patent for an improved metal powder production process and that the Company was on schedule for a 2017-Q1 assembly and first production run; • On January 23 and March 14, 2017, PyroGenesis provided updates and reaffirms that it is on schedule for 2017-Q1 assembly and first production run despite delays with suppliers; • On March 30, 2017, PyroGenesis announced that it had completed the assembly of its first powder production system, with its first powder run exceeding expectations. The Company also noted that the ramp-up, which was already underway, was expected to take place linearly over approximately four (4) months; • On April 25, 2017, PyroGenesis announced receipt of its first powder order from a multinational conglomerate, with the down payment already received, and market interest exceeding expectations; and • On June 7, 2017, PyroGenesis announced receipt of its second powder order.

The current production system is the first of many PyroGenesis expects to make to address an increasing need for metal powders in the AM Industry.1

Mr. P. Peter Pascali, President and CEO of PyroGenesis, provides an update on the developments within PyroGenesis’ AM business line in the following Q&A format:

Q. Very very busy year so far for PyroGenesis and now we see the creation of PyroGenesis Additive.

A. Most definitely. Over the top. Exceeds our wildest expectations on every front.

Q. So are we finally going to see some movement with respect to the spin-off announced in April 2016?

A. Most certainly. The creation of PyroGenesis Additive is definitely the first step in spinning off our AM capabilities, which we announced over a year ago, into a standalone entity. We are dedicated to a spin-off for a number of reasons, all of which speak to increasing shareholder value. A spin-off, should be less complicated to analyze and we feel it would appeal to a larger investor audience who, although interested in investing in the AM Industry, have little or no interest in either understanding, or investing in, our other business lines (i.e. waste destruction, DROSRITE™, PUREVAPTM, amongst others), and a spin-off could help avoid this. Concurrently, we feel a spin-off would provide for a clearer, and better defined, entity, which third parties could consider for joint ventures, strategic alliances, or even an acquisition of PyroGenesis Additive.

Q. Why the delay in the spin-off?

Simply put: the world of AM has changed significantly since we first announced our intention to spin-off our additive manufacturing capabilities; and, may I add, all for the better for PyroGenesis’ shareholders.

Over a year ago, we announced our intention to start producing speciality powders for the AM Industry which garnered such interest that it became apparent that PyroGenesis’ shareholders might be best served by spinning off this business line.

As such, we announced our intention to spin off our AM capabilities, but while completing our analysis of the various options available, and just when we were about to make a decision, General Electric (“GE”) announced its acquisition of Arcam, in November 2016, for approximately US$700MM. Now this is noteworthy because Arcam’s subsidiary, AP&C, which was acquired by Arcam for Can$35MM in 20142, produced powders using PyroGenesis’ old proprietary technology under an agreement which precluded PyroGenesis from competing against AP&C until 2012. Of particular note, through Arcam, AP&C became the dominant supplier of speciality powders to the AM Industry. GE’s acquisition of Arcam, and by extension of AP&C, has effectively disrupted the supply chain of speciality powders in the AM Industry which has caused end users of such powders to re-examine their access to them, all while PyroGenesis is re-entering the market as a supplier of such powders.

It would not have been prudent for us to carry on with a spin-off merely because we announced such intentions a few months earlier, without fully analyzing the ramifications of the changing landscape.

1 Wohlers Report 2016 (ISBN 978-0-9913332-2-6) 2http://advancedpowders.com/news/arcam-to-make-strategic-acqu…

Q. Where does the spin-off stand and what should investors expect?