Meinolf's SMART-GRID-Thread - 500 Beiträge pro Seite

eröffnet am 19.01.09 13:35:57 von

neuester Beitrag 12.09.19 14:12:39 von

neuester Beitrag 12.09.19 14:12:39 von

Beiträge: 307

ID: 1.147.666

ID: 1.147.666

Aufrufe heute: 0

Gesamt: 33.826

Gesamt: 33.826

Aktive User: 0

Top-Diskussionen

| Titel | letzter Beitrag | Aufrufe |

|---|---|---|

| vor 50 Minuten | 111 | |

| gestern 09:54 | 100 | |

| 05.12.14, 17:15 | 65 | |

| vor 1 Stunde | 64 | |

| 06.03.17, 11:10 | 64 | |

| 03.04.08, 18:47 | 44 | |

| gestern 21:21 | 43 | |

| 08.05.09, 09:35 | 38 |

Meistdiskutierte Wertpapiere

| Platz | vorher | Wertpapier | Kurs | Perf. % | Anzahl | ||

|---|---|---|---|---|---|---|---|

| 1. | 1. | 18.161,01 | +1,36 | 217 | |||

| 2. | 3. | 0,1885 | -0,26 | 90 | |||

| 3. | 2. | 1,1800 | -14,49 | 77 | |||

| 4. | 5. | 9,3500 | +1,14 | 60 | |||

| 5. | 4. | 169,14 | -0,61 | 50 | |||

| 6. | Neu! | 0,4400 | +3,53 | 36 | |||

| 7. | Neu! | 4,7950 | +6,91 | 34 | |||

| 8. | Neu! | 11,905 | +14,97 | 31 |

Mit fortschreitendem Ausbau der Erneuerbaren Energien wird es immer wichtiger werden, die Entwicklung des ganzen Systems der Strom- und Energieerzeugung zu betrachten und zu optimieren.

Fossile Energien sind "dispatchable", d.h. im Wesentlichen dann einsetzbar, wenn der Bedarf da ist.

Erneuerbare stehen dann zur Verfügung, wenn die Natur sie bereitstellt.

Um Nachfrage und Angebot zur Deckung zu bringen, werden alle Arten von Technologien zu

-Speicherung

-Netzmanagement

-Demand Management

etc.

zum Einsatz kommen müssen.

Ich verfolge bereits eine kleine anzahl von Firmen, die Angebote in dieser richtung machen, würde aber gerne auch eine Diskussionsplattform für nicht-firmenspezifische Thmen haben.

Deshalb dieser Thread.

Fossile Energien sind "dispatchable", d.h. im Wesentlichen dann einsetzbar, wenn der Bedarf da ist.

Erneuerbare stehen dann zur Verfügung, wenn die Natur sie bereitstellt.

Um Nachfrage und Angebot zur Deckung zu bringen, werden alle Arten von Technologien zu

-Speicherung

-Netzmanagement

-Demand Management

etc.

zum Einsatz kommen müssen.

Ich verfolge bereits eine kleine anzahl von Firmen, die Angebote in dieser richtung machen, würde aber gerne auch eine Diskussionsplattform für nicht-firmenspezifische Thmen haben.

Deshalb dieser Thread.

Antwort auf Beitrag Nr.: 36.402.747 von meinolf67 am 19.01.09 13:35:57Ein paar konkrete Fragen habe ich auch schon.

Weiß jemand was über:

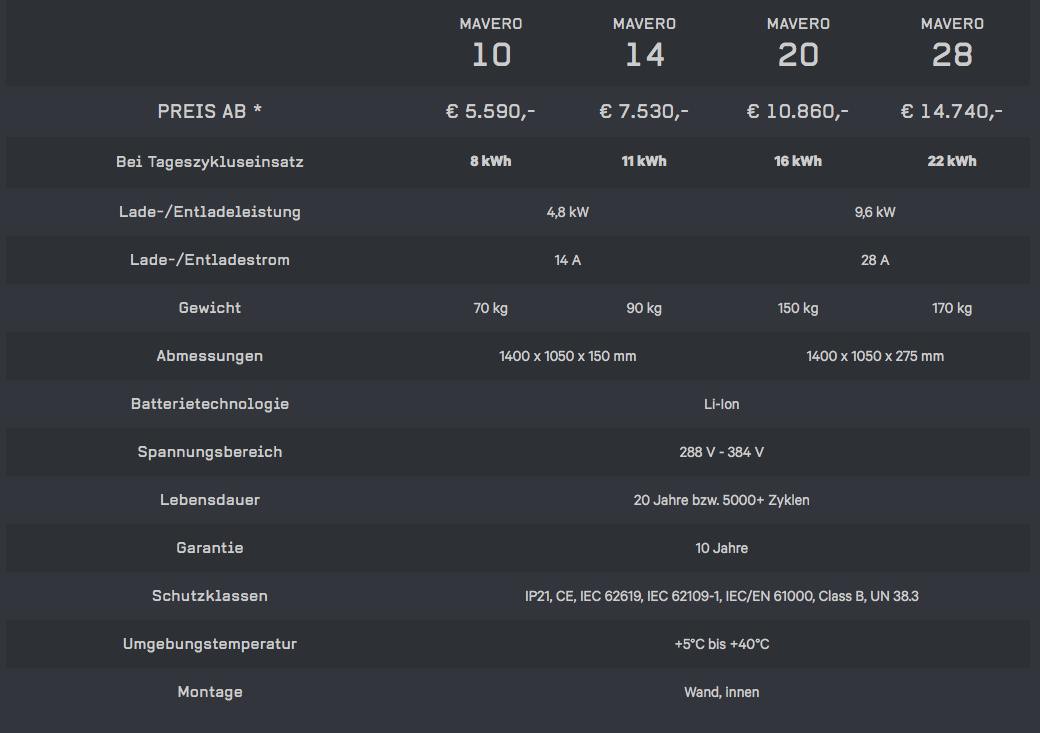

1) konkrete Kosten von Batterietechnologien; Invest pro kWh, Lebensdauer, Betriebskosten,...

2) GROßE konkrete Projekte zum Demand Management; so nach dem Motto: riesiges Kühlhaus wird genau dann runtergekühlt , wenn Last-Tal und weniger gekühlt, wenn Lastspitze...

3) Quellen zur Struktur der Elektrizitätsnetze, der Engpässe, künftige Entwicklungsrichtungen,...

Weiß jemand was über:

1) konkrete Kosten von Batterietechnologien; Invest pro kWh, Lebensdauer, Betriebskosten,...

2) GROßE konkrete Projekte zum Demand Management; so nach dem Motto: riesiges Kühlhaus wird genau dann runtergekühlt , wenn Last-Tal und weniger gekühlt, wenn Lastspitze...

3) Quellen zur Struktur der Elektrizitätsnetze, der Engpässe, künftige Entwicklungsrichtungen,...

Antwort auf Beitrag Nr.: 36.402.775 von meinolf67 am 19.01.09 13:39:57Beispiel für einen dezentralen Ansatz nach 2):

Ice Bear 30 Hybrid Air Conditioner

Discover the Power of Ice

Ice Energy’s Ice Bear® Hybrid Air Conditioner is the industry's first integrated energy storage and HVAC solution specifically designed for small to medium-sized commercial buildings.

By using cleaner, more efficient and less expensive nighttime power to produce and store energy for use the next day, the Ice Bear 30 Hybrid Air Conditioner provides efficient cooling using only a fraction of the peak energy required by conventional systems, dramatically lowering electricity costs and reducing greenhouse gas emissions.

Air conditioning energy demand – typically 40-50% of a building’s electricity use during expensive peak hours – can be reduced by as much as 95%.

Combining conventional air conditioning with Ice Energy’s ground-breaking energy storage technology and using each when it’s most efficient and cost-effective, hybrid cooling saves money and reduces the impact on the environment. Together, this unique hybrid system surpasses the overall efficiency and performance of conventional equipment alone.

Together, this unique hybrid system surpasses the overall efficiency and performance of conventional equipment alone.

Ice Bear 30 Hybrid Air Conditioner

Discover the Power of Ice

Ice Energy’s Ice Bear® Hybrid Air Conditioner is the industry's first integrated energy storage and HVAC solution specifically designed for small to medium-sized commercial buildings.

By using cleaner, more efficient and less expensive nighttime power to produce and store energy for use the next day, the Ice Bear 30 Hybrid Air Conditioner provides efficient cooling using only a fraction of the peak energy required by conventional systems, dramatically lowering electricity costs and reducing greenhouse gas emissions.

Air conditioning energy demand – typically 40-50% of a building’s electricity use during expensive peak hours – can be reduced by as much as 95%.

Combining conventional air conditioning with Ice Energy’s ground-breaking energy storage technology and using each when it’s most efficient and cost-effective, hybrid cooling saves money and reduces the impact on the environment. Together, this unique hybrid system surpasses the overall efficiency and performance of conventional equipment alone.

Together, this unique hybrid system surpasses the overall efficiency and performance of conventional equipment alone.

Ice Energy Launches Utility-Scale Smart Grid Tools For RE Integration

in News Departments > FYI

by SI Staff on Thursday 15 January 2009

email the content item print the content item

Ice Energy, a provider of smart grid and distributed energy-storage solutions for leveling peak energy demand, plans expand its offerings to focus on utility-scale deployment. The company's technology involves lossless distributed energy storage with closed-loop, two-way control and a software infrastructure to permanently reshape the load curve.

Unlike load management cycling or other curtailment programs that harm customer comfort and economic productivity, Ice Energy permanently and transparently shifts cooling energy consumption to off-peak hours, with no negative impact to consumers, the company says.

The technology is designed to complement intermittent, off-peak renewable portfolio assets such as wind and solar, enabling utilities to shift significant load to off-peak hours when the energy delivery system is both underutilized and more thermally efficient.

SOURCE: Ice Energy

in News Departments > FYI

by SI Staff on Thursday 15 January 2009

email the content item print the content item

Ice Energy, a provider of smart grid and distributed energy-storage solutions for leveling peak energy demand, plans expand its offerings to focus on utility-scale deployment. The company's technology involves lossless distributed energy storage with closed-loop, two-way control and a software infrastructure to permanently reshape the load curve.

Unlike load management cycling or other curtailment programs that harm customer comfort and economic productivity, Ice Energy permanently and transparently shifts cooling energy consumption to off-peak hours, with no negative impact to consumers, the company says.

The technology is designed to complement intermittent, off-peak renewable portfolio assets such as wind and solar, enabling utilities to shift significant load to off-peak hours when the energy delivery system is both underutilized and more thermally efficient.

SOURCE: Ice Energy

Ice Energy set to change industry

By Kristen Tatti

Northern Colorado Business Report

WINDSOR - The past year has been full of accolades for Windsor-based Ice Energy Inc., but this year will be about leveraging the praise into an industry-changing, revenue-generating energy industry powerhouse.

In early June, the company officially launched its next generation of cooling technology - the Ice Bear 30 Hybrid Air Conditioner and companion Ice-Ready Rooftop Unit. The launch represents a huge milestone for the company as it moves toward mass deployment deals, fulfilling its vision of outfitting every new commercial and residential building with the Ice Bear system.

Ice Energy was founded in 2003 with the Ice Bear 50, which uses a seemingly simplistic building cooling technology - ice. The Ice Bear is designed to switch the energy used for cooling buildings from the peak-use hours of the day to off-peak hours at night. Water frozen in the evening is used during the day to cool refrigerant for the air conditioning unit.

Ice Energy's solution is unique because it works with the more efficient refrigerant rather than just water. Buildings greater than two stories use water cooling systems because the water can maintain cooler temperatures for longer distances. But buildings of two stories and smaller make up 98 percent of all structures in the United States. That translates into a market of about 80 million cooling units, according to Ice Energy President Frank Ramirez.

"The Ice Bear 30 took lessons learned from the initial deployment and integrated it into the design," he said.

The Ice Bear 50 allowed the company to prove the technology, demonstrate its efficiency and learn how the challenges presented at different sites. It also garnered recognition and awards.

In early 2004, the Ice Bear received a Gold Award at the World's Best Technology contest, over 60 competing technologies. Ice Energy was also called "Most Promising Company" at the Energy Venture Fair IV in October 2003.

Doing more with less

The attention is not too surprising. A big push now is conservation, but Ramirez said that asking consumers to give up their comfort is a fruitless endeavor.

"It's not just how much we consume; but when we consume," he said, adding that it is 50 percent more efficient to generate and transmit energy at night to be stored for daytime use. Transmission energy loss during the day averages around 20 percent but only 6 percent in the evening. Therefore, even an appliance that uses slightly more energy will be more efficient and less consuming during off-peak hours.

"It is very difficult to change the way consumers behave," Ramirez said. "We can change the way energy is consumed at a facility by having technology do the work."

Ice Energy's technology is about efficiency, not conservation. To Ramirez, conservation is doing less with less and feeling good about it; efficiency is doing more with less by being smart about how it's done.

One of the big breakthroughs for new system is its ability to work with any equipment. The Ice Bear 30 is designed so that it can be outfitted on existing HVAC systems, and available to end-users as an out-of-the-box solution. Ice Energy is also working with air-conditioning industry leaders Trane Inc. and Carrier Corp. to offer cooling units with the Ice Bear 30 already integrated through its resellers, with a similar deal with another major manufacturer in the works.

"The technology itself is only a small part of this," he said.

During the next year, Ramirez said a lot of focus will be put on developing a business model wherein there will be no expense to the consumer. And he isn't talking about a good return on investment.

"The end consumer will be the beneficiary of the technology and the host of the technology," Ramirez explained, but the utility companies will be Ice Energy's customers. Ideally, utility companies would deploy Ice Energy's technology in the same way those companies would deliver any resources to the end-users.

The company is already working with a few California utilities, including Pacific Gas & Electric Co. and Southern California Edison.

"We're in very advanced discussions with a number of large utilities for deployment (of this technology) on a utility scale," he said.

Ice Energy sees the business model as a win-win-win: good for consumers, for utilities and for the company. The company is discussing deployments of 50 to 100 megawatt with utilities. It would take about 14,000 Ice Bear 30 units to fulfill a 100-megawatt deployment. The company manufactured a few hundred units last year.

"The ramp-up in scale is huge," Ramirez said.

Funding like a power plant

In order to fund such an increase in production, Ice Energy is in discussions to land large infrastructure funds more typically used to build power plants. Ramirez said that because the Ice Bear mitigates the need to add generation capacity, it is like a power plant, just storing power rather than generating it.

"In every respect, switching from peak to off-peak demand is like building a new power plant," said Pete Higgens, Ice Energy board member. Essentially, the Ice Bear 30 is a cheaper, less regulated way to build power generation capacity.

Higgens, a former Microsoft executive, went to graduate school with Ramirez and first heard of Ice Energy at a reunion in 2003.

"I view it in a macro sense as an incredible creator of value," he said. "It solves a huge problem."

Higgens said the company is in the process of changing its accolades into revenue.

"I think it's a time of acceleration," he said.

Ice Energy's board of directors and advisory board play a big role in the company's direction and future. The roster reads like a who's who of industry and business, even counting retired U.S. Army General Norman Schwarzkopf as its leadership adviser.

Joe Desmond was able to learn about Ice Energy as a direct observer. Desmond served as the chair of the California Energy Commission when he first saw the product at work in technical evaluations in the state.

"It became clear to me that the technology could solve a lot of the energy problems in California," he said. "The ability to shift 90-plus percent of on-peak demand to off-peak is a great benefit."

Now as a member of the board of directors, Desmond is able to bring his many years of experience working in various aspects of the energy industry to Ice Energy.

"I like to think that I bring a very broad perspective about how the energy industry will evaluate the technology," he said.

For Desmond, the decision to become involved with Ice Energy was about both the experience of the management team and the strength of the technology.

"They had clearly invested a lot in the technology and in testing," he said. "Equally important is the market opportunity."

The energy industry, he explained, has been largely preoccupied with generation, transmission and demand. Energy storage is a virtually untapped aspect of the business.

"This has significant potential to change the industry," he said.

Desmond explained that the launch of the Ice Bear 30 is an accomplishment on many levels. It is a standard unit deployable on a plug-and-play basis; it decreases the cost of installation of new units and integration for existing units and includes a method for real-time communication for monitoring performance.

"Although on the surface it appears to be simplistic, they have significant intellectual property around how to intelligently store energy," Desmond said.

Ice Energy currently has seven patents, issued and owned, and more than 100 in process.

"We're not a manufacturing company," Ramirez said, explaining that research and development is the company's true competency. "The process is one of continuous improvement and refinement."

Greater aspirations

Ice Energy is already cooling the office and industrial building market, but has greater aspirations. Ramirez said that work is ongoing to develop an appropriately intelligent system for cooling residential properties. The company has had about a dozen test units operating for around two years, mining information for further development. The key is to provide consumers with an absolutely simple plug-and-play solution.

"Working with the residential marketplace has different problems and solutions," Ramirez said.

In addition to research and realizing the business model, Ice Energy is also working on landing the financing it will need to ramp up its growth. The company is in the process now of attracting a $25 million Series B round of financing.

"We're into the stretch run with three prospective partners," he said.

A $26 million Series A round came in June 2007 though a partnership led by investment banking powerhouse Goldman Sachs. Ramirez explained that about half of that funding went to debt and note conversion.

Raising capital for the company now should be a walk in the park compared to efforts in the early days.

"When we first started talking about storage five years ago, we were seen as strange people with a strange idea. Now we're seen as visionaries in the mainstream," Ramirez said. "We've just begun to get the momentum and mass to tell this story."

By Kristen Tatti

Northern Colorado Business Report

WINDSOR - The past year has been full of accolades for Windsor-based Ice Energy Inc., but this year will be about leveraging the praise into an industry-changing, revenue-generating energy industry powerhouse.

In early June, the company officially launched its next generation of cooling technology - the Ice Bear 30 Hybrid Air Conditioner and companion Ice-Ready Rooftop Unit. The launch represents a huge milestone for the company as it moves toward mass deployment deals, fulfilling its vision of outfitting every new commercial and residential building with the Ice Bear system.

Ice Energy was founded in 2003 with the Ice Bear 50, which uses a seemingly simplistic building cooling technology - ice. The Ice Bear is designed to switch the energy used for cooling buildings from the peak-use hours of the day to off-peak hours at night. Water frozen in the evening is used during the day to cool refrigerant for the air conditioning unit.

Ice Energy's solution is unique because it works with the more efficient refrigerant rather than just water. Buildings greater than two stories use water cooling systems because the water can maintain cooler temperatures for longer distances. But buildings of two stories and smaller make up 98 percent of all structures in the United States. That translates into a market of about 80 million cooling units, according to Ice Energy President Frank Ramirez.

"The Ice Bear 30 took lessons learned from the initial deployment and integrated it into the design," he said.

The Ice Bear 50 allowed the company to prove the technology, demonstrate its efficiency and learn how the challenges presented at different sites. It also garnered recognition and awards.

In early 2004, the Ice Bear received a Gold Award at the World's Best Technology contest, over 60 competing technologies. Ice Energy was also called "Most Promising Company" at the Energy Venture Fair IV in October 2003.

Doing more with less

The attention is not too surprising. A big push now is conservation, but Ramirez said that asking consumers to give up their comfort is a fruitless endeavor.

"It's not just how much we consume; but when we consume," he said, adding that it is 50 percent more efficient to generate and transmit energy at night to be stored for daytime use. Transmission energy loss during the day averages around 20 percent but only 6 percent in the evening. Therefore, even an appliance that uses slightly more energy will be more efficient and less consuming during off-peak hours.

"It is very difficult to change the way consumers behave," Ramirez said. "We can change the way energy is consumed at a facility by having technology do the work."

Ice Energy's technology is about efficiency, not conservation. To Ramirez, conservation is doing less with less and feeling good about it; efficiency is doing more with less by being smart about how it's done.

One of the big breakthroughs for new system is its ability to work with any equipment. The Ice Bear 30 is designed so that it can be outfitted on existing HVAC systems, and available to end-users as an out-of-the-box solution. Ice Energy is also working with air-conditioning industry leaders Trane Inc. and Carrier Corp. to offer cooling units with the Ice Bear 30 already integrated through its resellers, with a similar deal with another major manufacturer in the works.

"The technology itself is only a small part of this," he said.

During the next year, Ramirez said a lot of focus will be put on developing a business model wherein there will be no expense to the consumer. And he isn't talking about a good return on investment.

"The end consumer will be the beneficiary of the technology and the host of the technology," Ramirez explained, but the utility companies will be Ice Energy's customers. Ideally, utility companies would deploy Ice Energy's technology in the same way those companies would deliver any resources to the end-users.

The company is already working with a few California utilities, including Pacific Gas & Electric Co. and Southern California Edison.

"We're in very advanced discussions with a number of large utilities for deployment (of this technology) on a utility scale," he said.

Ice Energy sees the business model as a win-win-win: good for consumers, for utilities and for the company. The company is discussing deployments of 50 to 100 megawatt with utilities. It would take about 14,000 Ice Bear 30 units to fulfill a 100-megawatt deployment. The company manufactured a few hundred units last year.

"The ramp-up in scale is huge," Ramirez said.

Funding like a power plant

In order to fund such an increase in production, Ice Energy is in discussions to land large infrastructure funds more typically used to build power plants. Ramirez said that because the Ice Bear mitigates the need to add generation capacity, it is like a power plant, just storing power rather than generating it.

"In every respect, switching from peak to off-peak demand is like building a new power plant," said Pete Higgens, Ice Energy board member. Essentially, the Ice Bear 30 is a cheaper, less regulated way to build power generation capacity.

Higgens, a former Microsoft executive, went to graduate school with Ramirez and first heard of Ice Energy at a reunion in 2003.

"I view it in a macro sense as an incredible creator of value," he said. "It solves a huge problem."

Higgens said the company is in the process of changing its accolades into revenue.

"I think it's a time of acceleration," he said.

Ice Energy's board of directors and advisory board play a big role in the company's direction and future. The roster reads like a who's who of industry and business, even counting retired U.S. Army General Norman Schwarzkopf as its leadership adviser.

Joe Desmond was able to learn about Ice Energy as a direct observer. Desmond served as the chair of the California Energy Commission when he first saw the product at work in technical evaluations in the state.

"It became clear to me that the technology could solve a lot of the energy problems in California," he said. "The ability to shift 90-plus percent of on-peak demand to off-peak is a great benefit."

Now as a member of the board of directors, Desmond is able to bring his many years of experience working in various aspects of the energy industry to Ice Energy.

"I like to think that I bring a very broad perspective about how the energy industry will evaluate the technology," he said.

For Desmond, the decision to become involved with Ice Energy was about both the experience of the management team and the strength of the technology.

"They had clearly invested a lot in the technology and in testing," he said. "Equally important is the market opportunity."

The energy industry, he explained, has been largely preoccupied with generation, transmission and demand. Energy storage is a virtually untapped aspect of the business.

"This has significant potential to change the industry," he said.

Desmond explained that the launch of the Ice Bear 30 is an accomplishment on many levels. It is a standard unit deployable on a plug-and-play basis; it decreases the cost of installation of new units and integration for existing units and includes a method for real-time communication for monitoring performance.

"Although on the surface it appears to be simplistic, they have significant intellectual property around how to intelligently store energy," Desmond said.

Ice Energy currently has seven patents, issued and owned, and more than 100 in process.

"We're not a manufacturing company," Ramirez said, explaining that research and development is the company's true competency. "The process is one of continuous improvement and refinement."

Greater aspirations

Ice Energy is already cooling the office and industrial building market, but has greater aspirations. Ramirez said that work is ongoing to develop an appropriately intelligent system for cooling residential properties. The company has had about a dozen test units operating for around two years, mining information for further development. The key is to provide consumers with an absolutely simple plug-and-play solution.

"Working with the residential marketplace has different problems and solutions," Ramirez said.

In addition to research and realizing the business model, Ice Energy is also working on landing the financing it will need to ramp up its growth. The company is in the process now of attracting a $25 million Series B round of financing.

"We're into the stretch run with three prospective partners," he said.

A $26 million Series A round came in June 2007 though a partnership led by investment banking powerhouse Goldman Sachs. Ramirez explained that about half of that funding went to debt and note conversion.

Raising capital for the company now should be a walk in the park compared to efforts in the early days.

"When we first started talking about storage five years ago, we were seen as strange people with a strange idea. Now we're seen as visionaries in the mainstream," Ramirez said. "We've just begun to get the momentum and mass to tell this story."

Antwort auf Beitrag Nr.: 36.402.775 von meinolf67 am 19.01.09 13:39:57Schau mal unter E-Energy ...

Die Bundesregierung fördert gerade ein paar Projekte in der Richtung

Die Bundesregierung fördert gerade ein paar Projekte in der Richtung

Antwort auf Beitrag Nr.: 36.403.921 von vvogel am 19.01.09 15:56:23Danke für den Tip

hallo,

mich würden auch mal firmen bzw. startups interessieren, die in das thema smart grid reinpassen und an der börse handelbar sind.

kann mir jemand eine kleine übersicht geben?

wäre nett!

danke

h.

mich würden auch mal firmen bzw. startups interessieren, die in das thema smart grid reinpassen und an der börse handelbar sind.

kann mir jemand eine kleine übersicht geben?

wäre nett!

danke

h.

gerade bei Spiegel-Online (daher im Zweifel alles sehr ungenau bis vollkommen falsch...  )

)

Das Stromnetz der Zukunft soll eine gewaltige Kommunikationsplattform werden - daran arbeiten Firmen wie Silver Spring aus Kalifornien. Ziel: Verbraucher sollen ihren Energiebedarf selbst genau kontrollieren können. Investoren überschütten die Startups mit Geld, Experten wittern einen Mega-Boom.

http://www.spiegel.de/wirtschaft/0,1518,612827,00.html

)

)Das Stromnetz der Zukunft soll eine gewaltige Kommunikationsplattform werden - daran arbeiten Firmen wie Silver Spring aus Kalifornien. Ziel: Verbraucher sollen ihren Energiebedarf selbst genau kontrollieren können. Investoren überschütten die Startups mit Geld, Experten wittern einen Mega-Boom.

http://www.spiegel.de/wirtschaft/0,1518,612827,00.html

habe ich auch gelesen und bin gerade auf der Suche nach entsprechenden AGs deren Aktien man handeln kann. Bin für jeden Tip dankbar.

Antwort auf Beitrag Nr.: 36.828.997 von Scar am 23.03.09 19:57:34mal ein paar Anregungen (z.T. (OTC-)MicroCaps, deswegen Handelbarkeit nicht unbedingt gegeben) für die weitere Recherche:

RuggedCom (CA78131P2017)

Telvent (ES0178495034)

Ambient (US02318N1028)

Beacon Power (US0736771066)

Itron (US4657411066)

Power-One (US7393081044)

PowerSecure (US73936N1054)

EnerNOC (US2927641074)

aber natürlich auch eine SMA (DE000A0DJ6J9) die aus meiner Sicht deutliche Potentiale auch abseits von PV hat (siehe z.B. Backup-Lösungen)

RuggedCom (CA78131P2017)

Telvent (ES0178495034)

Ambient (US02318N1028)

Beacon Power (US0736771066)

Itron (US4657411066)

Power-One (US7393081044)

PowerSecure (US73936N1054)

EnerNOC (US2927641074)

aber natürlich auch eine SMA (DE000A0DJ6J9) die aus meiner Sicht deutliche Potentiale auch abseits von PV hat (siehe z.B. Backup-Lösungen)

Antwort auf Beitrag Nr.: 36.828.997 von Scar am 23.03.09 19:57:34aus meinen musterdepot:

ITRON INC. 888379

Enernoc Inc. A0MSDC

Duke Energy Corp. A0JJ5P

Ruggedcom Inc. A0MVSY

Xcel Energy, Inc. 2614807

WHIRLPOOL CORP. 856331

Echelon Corporation 2285377

DIGI INTERNATIONAL INC. 878008

Comverge Inc. A0MN5C

Telvent GIT A0DK9P

ITRON INC. 888379

Enernoc Inc. A0MSDC

Duke Energy Corp. A0JJ5P

Ruggedcom Inc. A0MVSY

Xcel Energy, Inc. 2614807

WHIRLPOOL CORP. 856331

Echelon Corporation 2285377

DIGI INTERNATIONAL INC. 878008

Comverge Inc. A0MN5C

Telvent GIT A0DK9P

smart meter - smart home:

http://www.youtube.com/watch?v=rRJJBRbq2FM

http://www.youtube.com/watch?v=rRJJBRbq2FM

Four utilities sign contracts with EnerNOC

March 24, 2009 09:18

EnerNOC Inc., a Boston company that helps utilities manage and conserve electricity use, said that four utilities operating in Maryland have signed contracts to avail themselves of EnerNOC services.

The utilities are Allegheny Power, Baltimore Gas and Electric, Delmarva Power and Light Co., and Potomac Electric Power Co., and the contracts will result in EnerNOC providing 250 megawatts of demand response capacity in the state of Maryland, EnerNOC said.

To read today's press release from EnerNOC, please click here.

(By Chris Reidy, Globe staff)

Gruß Karlll

March 24, 2009 09:18

EnerNOC Inc., a Boston company that helps utilities manage and conserve electricity use, said that four utilities operating in Maryland have signed contracts to avail themselves of EnerNOC services.

The utilities are Allegheny Power, Baltimore Gas and Electric, Delmarva Power and Light Co., and Potomac Electric Power Co., and the contracts will result in EnerNOC providing 250 megawatts of demand response capacity in the state of Maryland, EnerNOC said.

To read today's press release from EnerNOC, please click here.

(By Chris Reidy, Globe staff)

Gruß Karlll

das ist meine favorit

Beacon Power (US0736771066)

Beacon Power (US0736771066)

Smart Meter: Neue Standards machen dezentrale Energieversorgung effizient (31.03.2009)

Die Vorteile einer dezentralen Energieversorgung liegen auf der Hand: Die Nähe zum Endverbraucher ermöglicht verlustarme kurze Übertragungswege. Auch regenerative Energien, z.B. private Solaranlagen, können in dezentralen Stromnetzen effektiv genutzt werden. Das Forschungsprojekt SMEDEA an der TU Dortmund soll jetzt Wege und Standards erarbeiten, wie die gemessenen Daten von neuen elektronischen Zählern, welche ab 2010 auch dem Endkunden angeboten werden müssen (den so genannten Smart Metern) für die Steuerung und den wirtschaftlichen Betrieb vernetzter dezentraler Energieerzeuger genutzt werden können.

TU DdortmunNRW-Wirtschaftsministerin Christa Thoben überreichte heute, am 30. März, persönlich den Bewilligungsbescheid über eine Förderung in Höhe von 370.000 €. SMEDEA (Standardisiertes Smart Metering als Schlüsselfunktion für die Energieeffizienz von dezentralen Energieumwandlungsanlagen) konnte sich im Wettbewerb "Energie.NRW" durchsetzen und wird von Prof. Christian Rehtanz vom Lehrstuhl für Energiesysteme und Energiewirtschaft der Fakultät Elektrotechnik und Informationstechnik der TU Dortmund koordiniert. Partner auf Seiten der Industrie sind die EVB Energie AG, einer der marktführenden Dienstleiter für Energieversorgungsunternehmen sowie die Energieversorgung Oelde GmbH.

"Ich freue mich, dieses Smart Metering Projekt heute auf den Weg bringen zu können. Denn, Energieeffizienz braucht auch Verbrauchstransparenz in den Haushalten. Mit intelligenten Zählern machen wir einen wichtigen Schritt hierzu", sagte Wirtschaftsministerin Christa Thoben. "Mit der Entwicklung und dem Einsatz der elektronischen Haushaltszähler eröffnen sich einerseits neue Möglichkeiten, die Effizienz des Stromverbrauchs beim Kunden zu steigern und Anreize zum Einsparen von Strom zu geben. Andererseits bringt es auch den Stromversorgern Vorteile z.B. durch die Fernablesung und eine vereinfachte Rechnungslegung."

Das Forschungsprojekt nutzt die Umsetzung der EU-Richtlinie 2006/32/EG "Energieeffizienz und Energiedienstleistungen", die eine zeitnahe Information der Endverbraucher über ihren Energieverbrauch und die individuelle Nutzung fordert. Jeder Stromkunde soll so seinen Energieverbrauch selbst beeinflussen und damit auch reduzieren können. Voraussetzung hierfür ist ein flächendeckender Einsatz von Smart Metering-Systemen, die - mit Kommunikationsschnittstellen ausgestattet - auch für ein effektives Energiemanagement insbesondere von dezentralen Energieerzeugern genutzt werden können.

In der praktischen Umsetzung sehen sich die Wissenschaftler jedoch mit einer Fülle von Problemen konfrontiert, die in diesem Zusammenhang ein optimales Zusammenwirken von Zählerdatenverarbeitung, Netzplanung und Netzbetrieb verhindert. Die informationstechnische Vernetzung der Komponenten stellt eine große technologische Herausforderung dar, insbesondere vor dem Hintergrund, dass die Hersteller von elektronischen Zählern zur Zeit unterschiedliche Kommunikationsstandards verwenden. Hierfür gilt es, Standards und Konzepte zu entwickeln und diese in der Praxis zu erproben. Zusätzlich müssen z.B. auch datenschutzrechtliche Implikationen berücksichtigt werden.

Der Projektpartner Energieversorgung Oelde GmbH wird die Inbetriebnahme eines Smart Metering-Netzes mit ca. 150 einzelnen Zählern durchführen. Dieses Pilotprojekt wird als Grundlage für die Feldversuche verwendet. Die zeitnahe automatische Verbrauchsdatenerfassung wird durch die EVB Energie AG im Rahmen dieses Pilotprojekts umgesetzt und realisiert. Die Testumgebung in den Laboren des Lehrstuhls für Energiesysteme und Energiewirtschaft der TU Dortmund bietet die Plattform für die theoretischen Untersuchungen, bevor die Anlagen im Netz installiert werden.

Insgesamt drei Jahre wollen die Projektpartner das System planen, entwickeln und in der Praxis erproben. Die Ergebnisse des Pilotprojekts sollen zu 100% auf herkömmliche Netze unabhängig von ihrer Größe übertragbar sein und sollen deren Wirtschaftlichkeit als auch den effizienten Einsatz der dezentralen Energieerzeugung wesentlich verbessern.

Quelle: TU Dortmund

Die Vorteile einer dezentralen Energieversorgung liegen auf der Hand: Die Nähe zum Endverbraucher ermöglicht verlustarme kurze Übertragungswege. Auch regenerative Energien, z.B. private Solaranlagen, können in dezentralen Stromnetzen effektiv genutzt werden. Das Forschungsprojekt SMEDEA an der TU Dortmund soll jetzt Wege und Standards erarbeiten, wie die gemessenen Daten von neuen elektronischen Zählern, welche ab 2010 auch dem Endkunden angeboten werden müssen (den so genannten Smart Metern) für die Steuerung und den wirtschaftlichen Betrieb vernetzter dezentraler Energieerzeuger genutzt werden können.

TU DdortmunNRW-Wirtschaftsministerin Christa Thoben überreichte heute, am 30. März, persönlich den Bewilligungsbescheid über eine Förderung in Höhe von 370.000 €. SMEDEA (Standardisiertes Smart Metering als Schlüsselfunktion für die Energieeffizienz von dezentralen Energieumwandlungsanlagen) konnte sich im Wettbewerb "Energie.NRW" durchsetzen und wird von Prof. Christian Rehtanz vom Lehrstuhl für Energiesysteme und Energiewirtschaft der Fakultät Elektrotechnik und Informationstechnik der TU Dortmund koordiniert. Partner auf Seiten der Industrie sind die EVB Energie AG, einer der marktführenden Dienstleiter für Energieversorgungsunternehmen sowie die Energieversorgung Oelde GmbH.

"Ich freue mich, dieses Smart Metering Projekt heute auf den Weg bringen zu können. Denn, Energieeffizienz braucht auch Verbrauchstransparenz in den Haushalten. Mit intelligenten Zählern machen wir einen wichtigen Schritt hierzu", sagte Wirtschaftsministerin Christa Thoben. "Mit der Entwicklung und dem Einsatz der elektronischen Haushaltszähler eröffnen sich einerseits neue Möglichkeiten, die Effizienz des Stromverbrauchs beim Kunden zu steigern und Anreize zum Einsparen von Strom zu geben. Andererseits bringt es auch den Stromversorgern Vorteile z.B. durch die Fernablesung und eine vereinfachte Rechnungslegung."

Das Forschungsprojekt nutzt die Umsetzung der EU-Richtlinie 2006/32/EG "Energieeffizienz und Energiedienstleistungen", die eine zeitnahe Information der Endverbraucher über ihren Energieverbrauch und die individuelle Nutzung fordert. Jeder Stromkunde soll so seinen Energieverbrauch selbst beeinflussen und damit auch reduzieren können. Voraussetzung hierfür ist ein flächendeckender Einsatz von Smart Metering-Systemen, die - mit Kommunikationsschnittstellen ausgestattet - auch für ein effektives Energiemanagement insbesondere von dezentralen Energieerzeugern genutzt werden können.

In der praktischen Umsetzung sehen sich die Wissenschaftler jedoch mit einer Fülle von Problemen konfrontiert, die in diesem Zusammenhang ein optimales Zusammenwirken von Zählerdatenverarbeitung, Netzplanung und Netzbetrieb verhindert. Die informationstechnische Vernetzung der Komponenten stellt eine große technologische Herausforderung dar, insbesondere vor dem Hintergrund, dass die Hersteller von elektronischen Zählern zur Zeit unterschiedliche Kommunikationsstandards verwenden. Hierfür gilt es, Standards und Konzepte zu entwickeln und diese in der Praxis zu erproben. Zusätzlich müssen z.B. auch datenschutzrechtliche Implikationen berücksichtigt werden.

Der Projektpartner Energieversorgung Oelde GmbH wird die Inbetriebnahme eines Smart Metering-Netzes mit ca. 150 einzelnen Zählern durchführen. Dieses Pilotprojekt wird als Grundlage für die Feldversuche verwendet. Die zeitnahe automatische Verbrauchsdatenerfassung wird durch die EVB Energie AG im Rahmen dieses Pilotprojekts umgesetzt und realisiert. Die Testumgebung in den Laboren des Lehrstuhls für Energiesysteme und Energiewirtschaft der TU Dortmund bietet die Plattform für die theoretischen Untersuchungen, bevor die Anlagen im Netz installiert werden.

Insgesamt drei Jahre wollen die Projektpartner das System planen, entwickeln und in der Praxis erproben. Die Ergebnisse des Pilotprojekts sollen zu 100% auf herkömmliche Netze unabhängig von ihrer Größe übertragbar sein und sollen deren Wirtschaftlichkeit als auch den effizienten Einsatz der dezentralen Energieerzeugung wesentlich verbessern.

Quelle: TU Dortmund

Antwort auf Beitrag Nr.: 36.830.792 von Keiretsu am 24.03.09 00:05:37

Will mich hier nur mal kurz vermerken.

Will mich hier nur mal kurz vermerken.

Why the "Smart Grid" may be a pipe-dream

by Bob Haavind, Editor-at-large, Photovoltaics World

The media has been full of stories about the coming of the "Smart Grid" for electric power, saving energy while incorporating distributed generators such as solar panels. More than $3B was put in the stimulus bill passed earlier this year to kick-start the transition.

But this Smart Grid vision may turn out to be a dream, suggested Howard Berke, founder and executive chairman of Konarka Technologies, Lowell, MA, at a lively PV America session in Philadelphia.

The US national grid is significantly old -- never having been bombed as were many electric systems in Europe and Asia -- and maintenance has been neglected, Berke explained. It would take decades to reach the Smart Grid vision being bandied about, but if the US spends most of its grid investment on maintenance of the existing infrastructure, other countries, even developing nations, may get there first, he warned.

As occasional widespread blackouts have shown, the electric grid in the US is not foolproof. "It's not dumb, but it could be a lot smarter," suggested Katherine Hamilton, president of the Gridwise Alliance, headquartered in Washington DC. Helping this happen is a major focus of her organization. Whereas in the past the grid grew helter-skelter across different regions, the Gridwise Alliance epitomizes current efforts to get a better coordinated, smoother transition to a smarter, much more energy-efficient system.

This process will take many years, even decades, according to Hamilton, "but a lot will happen in the next five years," she added.

The stimulus bill provides $3.5B for the Smart Grid, including $600M for demonstration projects on a 50-50 shared basis, according to Hamilton, but the various state public utility commissions (PUCs) will need to clear the way for this work to go forward. There is also $100M for workforce development, which is important because the electric utility workforce is aging. "There are no more power engineers," Hamilton noted, because EE students over past decades all favored electronics over power engineering.

The Gridwise Alliance, formed in 2003 in collaboration with the Department of Energy (DoE), has more than 85 members, including giants such as IBM, Google, GE, AT&T, and Cisco, but also many small companies along with universities and even investment companies. Every member, no matter how big or small, has the same voice, Hamilton claims.

"It is a consensus-building coalition, not an association," she emphasized, allowing it to take broad-based, unbiased positions. There are various working groups, such as the Smart Grid Policy Center, which does a lot of work with the states, she added. The coalition provides education and awareness of smart grid issues, and co-sponsors reports and white papers.

Hamilton listed a number of key policy initiatives, such a standards for renewable energy and energy efficiency, responses to climate change, transmission and cyber-security. The coalition prefers various measures to be embedded into broader bills, rather than pushing for special legislation, she noted. The group also helps with regulatory work, such as the FERC smart grid docket.

Climate legislation now making its way through Congress with a carbon cap and trade system will force change in energy markets, Hamilton concluded.

Game-changers

The electric grid is already getting a lot smarter through a wide range of utility initiatives, according to Michael Nix, senior market strategist for PJM Interconnection LLC, a group with 550 member companies stretching from the Mid-Atlantic region to Chicago. PJM's members serve more than 51M customers with a peak electric load of more than 145 MW, he said.

Facilities that have been added to the grid allowing functions such as the automation of distribution and substitution, energy storage, smart metering demand for load management, and market monitoring with SCADA and Phasor measurements. Network adapters allow attachments such as smart chargers or storage aggregators. Nix showed photos of long semi-trailers full of grid-scale storage units that can be hooked to the grid this way.

There will be far more energy storage of various kinds in the future, according to Nix, including flywheels, compressed air (which may come from wind), batteries, and capacitor banks with voltage regulators. The largest source of storage, he said, is still hydro -- water pumped up to holding ponds at night that can be released to drive turbines at times when demand is high. Pennsylvania, for example, has a 2000 MW hydro facility, he said.

"Energy storage will be a game-changer for the Smart Grid," added Hamilton.

Konarka's Berke sees big opportunities for innovative storage technologies, with more portable power to add flexibility to the grid -- but he feels that much innovation may be thwarted because of the fragmented approach to the Smart Grid involving state PUCs. Some regions are so far behind on maintenance that it will seem convenient to use new funds just to fix up the existing plant. And many innovative, promising technologies still require experimentation and investment, and some state PUCs may balk at this, he believes.

"If utilities try to drive new technologies, and the PUCs punish them for it, they could drive the system toward mediocrity," Berke said.

"Obama's got it right on the competitiveness of the US vs. developing nations," he added. If we don't push toward advanced grid capabilities we will fall behind other nations, many of them starting with a nearly clean slate.

As an illustration, Berke cited rising demand for power in New England, enough to call for the equivalent of one new power plant a year, but none are being built. Then he cited press accounts suggesting that $1 trillion might be spent over the next 10 years building new high power transmission lines to carry wind-generated power from the Dakotas to the Northeast. That money could be much better spent on distributed PV solar within the region, he believes, and that distributed generation would lead to a much better balanced power system.

Nix of PJM cited many solar PV projects already being initiated by electric utilities. Some are solar energy "farms," such as a 25MW facility of PS&G, with another 10MW at other sites. The New Jersey Housing Authority is planning 43MW of solar on rooftops, and the Exelon GROWS landfill site in Pennsylvania is the fifth biggest PV facility in the US, he said. Nix also showed how 4KW solar panels are now being hung on electric poles, already providing about 40MW of unmetered power into neighborhoods.

Rising power usage can also be tempered as consumers buy more smart appliances that save energy, he said. In the future homes will have meters that will show price variations during the day, so that users can make informed choices, like running the dishwasher at 2am.

Nix said that PJM is participating in the Mid-Atlantic Grid Interactive Car Consortium (MAGICC) with the U. of Delaware and a consortium including research institutes, other universities, and auto companies as well as electric utilities. The group is preparing for an upsurge in electric cars, which probably would be recharging batteries from 1-3am, and also would need scattered electric charging stations.

"Technology is not the challenge," agreed Berke, who suggested that IP (Internet Protocol) chips could be embedded in everything -- and maybe even everybody. Such implants are already common in pet dogs, he commented. What will be needed are the will, the national policies, investment, and the ability of all elements of the Smart Grid to work smoothly together.

Putting the "D" in DC

Technology allowing DC (direct current) power to be available from wall sockets is one thing he feels will make sense in the future. "Already 40% of the base load is DC," he said, and many more appliances are being made with DC brushless motors. Even further, lighting will be shifting to LEDs in the future, greatly increasing the DC load. Right now AC/DC converters are needed for everything that runs on DC -- he said that he tallied up 128 of them for the electronics and appliances just in his own home.

"This is a huge waste of energy," he pointed out.

An engineer in the session rose to challenge Berke's call for transmitting power as DC rather than AC. Long-distance, high-voltage transmission requires AC, he said, and there are safety factors favoring AC for wall plugs.

Berke countered that there are places in the world with both AC and DC outlets, such as Spain and the Netherlands. It has been shown, he said, that DC can be moved safely in micronetworks, and distributed energy sources like PV panels could directly supply DC power to them.

While the session showed that the electric grid will definitely get smarter, the question is how fast and how widely this will happen, and whether useful innovation with be fostered or thwarted along the way.

by Bob Haavind, Editor-at-large, Photovoltaics World

The media has been full of stories about the coming of the "Smart Grid" for electric power, saving energy while incorporating distributed generators such as solar panels. More than $3B was put in the stimulus bill passed earlier this year to kick-start the transition.

But this Smart Grid vision may turn out to be a dream, suggested Howard Berke, founder and executive chairman of Konarka Technologies, Lowell, MA, at a lively PV America session in Philadelphia.

The US national grid is significantly old -- never having been bombed as were many electric systems in Europe and Asia -- and maintenance has been neglected, Berke explained. It would take decades to reach the Smart Grid vision being bandied about, but if the US spends most of its grid investment on maintenance of the existing infrastructure, other countries, even developing nations, may get there first, he warned.

As occasional widespread blackouts have shown, the electric grid in the US is not foolproof. "It's not dumb, but it could be a lot smarter," suggested Katherine Hamilton, president of the Gridwise Alliance, headquartered in Washington DC. Helping this happen is a major focus of her organization. Whereas in the past the grid grew helter-skelter across different regions, the Gridwise Alliance epitomizes current efforts to get a better coordinated, smoother transition to a smarter, much more energy-efficient system.

This process will take many years, even decades, according to Hamilton, "but a lot will happen in the next five years," she added.

The stimulus bill provides $3.5B for the Smart Grid, including $600M for demonstration projects on a 50-50 shared basis, according to Hamilton, but the various state public utility commissions (PUCs) will need to clear the way for this work to go forward. There is also $100M for workforce development, which is important because the electric utility workforce is aging. "There are no more power engineers," Hamilton noted, because EE students over past decades all favored electronics over power engineering.

The Gridwise Alliance, formed in 2003 in collaboration with the Department of Energy (DoE), has more than 85 members, including giants such as IBM, Google, GE, AT&T, and Cisco, but also many small companies along with universities and even investment companies. Every member, no matter how big or small, has the same voice, Hamilton claims.

"It is a consensus-building coalition, not an association," she emphasized, allowing it to take broad-based, unbiased positions. There are various working groups, such as the Smart Grid Policy Center, which does a lot of work with the states, she added. The coalition provides education and awareness of smart grid issues, and co-sponsors reports and white papers.

Hamilton listed a number of key policy initiatives, such a standards for renewable energy and energy efficiency, responses to climate change, transmission and cyber-security. The coalition prefers various measures to be embedded into broader bills, rather than pushing for special legislation, she noted. The group also helps with regulatory work, such as the FERC smart grid docket.

Climate legislation now making its way through Congress with a carbon cap and trade system will force change in energy markets, Hamilton concluded.

Game-changers

The electric grid is already getting a lot smarter through a wide range of utility initiatives, according to Michael Nix, senior market strategist for PJM Interconnection LLC, a group with 550 member companies stretching from the Mid-Atlantic region to Chicago. PJM's members serve more than 51M customers with a peak electric load of more than 145 MW, he said.

Facilities that have been added to the grid allowing functions such as the automation of distribution and substitution, energy storage, smart metering demand for load management, and market monitoring with SCADA and Phasor measurements. Network adapters allow attachments such as smart chargers or storage aggregators. Nix showed photos of long semi-trailers full of grid-scale storage units that can be hooked to the grid this way.

There will be far more energy storage of various kinds in the future, according to Nix, including flywheels, compressed air (which may come from wind), batteries, and capacitor banks with voltage regulators. The largest source of storage, he said, is still hydro -- water pumped up to holding ponds at night that can be released to drive turbines at times when demand is high. Pennsylvania, for example, has a 2000 MW hydro facility, he said.

"Energy storage will be a game-changer for the Smart Grid," added Hamilton.

Konarka's Berke sees big opportunities for innovative storage technologies, with more portable power to add flexibility to the grid -- but he feels that much innovation may be thwarted because of the fragmented approach to the Smart Grid involving state PUCs. Some regions are so far behind on maintenance that it will seem convenient to use new funds just to fix up the existing plant. And many innovative, promising technologies still require experimentation and investment, and some state PUCs may balk at this, he believes.

"If utilities try to drive new technologies, and the PUCs punish them for it, they could drive the system toward mediocrity," Berke said.

"Obama's got it right on the competitiveness of the US vs. developing nations," he added. If we don't push toward advanced grid capabilities we will fall behind other nations, many of them starting with a nearly clean slate.

As an illustration, Berke cited rising demand for power in New England, enough to call for the equivalent of one new power plant a year, but none are being built. Then he cited press accounts suggesting that $1 trillion might be spent over the next 10 years building new high power transmission lines to carry wind-generated power from the Dakotas to the Northeast. That money could be much better spent on distributed PV solar within the region, he believes, and that distributed generation would lead to a much better balanced power system.

Nix of PJM cited many solar PV projects already being initiated by electric utilities. Some are solar energy "farms," such as a 25MW facility of PS&G, with another 10MW at other sites. The New Jersey Housing Authority is planning 43MW of solar on rooftops, and the Exelon GROWS landfill site in Pennsylvania is the fifth biggest PV facility in the US, he said. Nix also showed how 4KW solar panels are now being hung on electric poles, already providing about 40MW of unmetered power into neighborhoods.

Rising power usage can also be tempered as consumers buy more smart appliances that save energy, he said. In the future homes will have meters that will show price variations during the day, so that users can make informed choices, like running the dishwasher at 2am.

Nix said that PJM is participating in the Mid-Atlantic Grid Interactive Car Consortium (MAGICC) with the U. of Delaware and a consortium including research institutes, other universities, and auto companies as well as electric utilities. The group is preparing for an upsurge in electric cars, which probably would be recharging batteries from 1-3am, and also would need scattered electric charging stations.

"Technology is not the challenge," agreed Berke, who suggested that IP (Internet Protocol) chips could be embedded in everything -- and maybe even everybody. Such implants are already common in pet dogs, he commented. What will be needed are the will, the national policies, investment, and the ability of all elements of the Smart Grid to work smoothly together.

Putting the "D" in DC

Technology allowing DC (direct current) power to be available from wall sockets is one thing he feels will make sense in the future. "Already 40% of the base load is DC," he said, and many more appliances are being made with DC brushless motors. Even further, lighting will be shifting to LEDs in the future, greatly increasing the DC load. Right now AC/DC converters are needed for everything that runs on DC -- he said that he tallied up 128 of them for the electronics and appliances just in his own home.

"This is a huge waste of energy," he pointed out.

An engineer in the session rose to challenge Berke's call for transmitting power as DC rather than AC. Long-distance, high-voltage transmission requires AC, he said, and there are safety factors favoring AC for wall plugs.

Berke countered that there are places in the world with both AC and DC outlets, such as Spain and the Netherlands. It has been shown, he said, that DC can be moved safely in micronetworks, and distributed energy sources like PV panels could directly supply DC power to them.

While the session showed that the electric grid will definitely get smarter, the question is how fast and how widely this will happen, and whether useful innovation with be fostered or thwarted along the way.

Antwort auf Beitrag Nr.: 36.828.997 von Scar am 23.03.09 19:57:34Hallo!

Super, dass ich diesen Thread hier gefunden habe. Welche Smart Grid Aktien habt ihr so auf der WL? Ich bin derzeit in Echelon investiert und habe ein Auge auf PowerSecure und PSI geworfen. Bei der PSI AG überlege ich jetzt einzusteigen. Ich hatte zuletzt interessante Gespräche mit RWE Mitarbeitern (nicht die ganz hohe Führungsebene, aber schon etwas höhere Positionen) und dort setzt man voll auf Smart Grid. Darum habe sich RWE ja auch bei PSI eingekauft. Und auch Cisco Systems oder General Electric wollen ja in diesem Markt ein Wörtchen mitreden.

Kurz zu Echelon: Ein Umsatz von knapp 117 Mio. US$ (2008) wird dort derzeit mit einer Market Cap. von knapp 370 Mio. US$ bezahlt, ergo ein KUV von etwas über 3. Bisher schreibt die Firma zwar noch rote Zahlen (EBITDA: -23,66 Mio. US$), aber ich denke die Gewinnschwelle ist nicht mehr so fern. Und mit knapp 88 Mio. US$ Cash ist man gut durchfinanziert. Deshalb habe ich mich bisher für Echelon entschieden, zumal mir deren Technologie gefällt und mich auch der Chart überzeugt hat. Was meint Ihr zu Echelon?

LG Enzo

PS: Mehr Infos zu Echelon gibts auch unter: http://tr.im/utkQ

Super, dass ich diesen Thread hier gefunden habe. Welche Smart Grid Aktien habt ihr so auf der WL? Ich bin derzeit in Echelon investiert und habe ein Auge auf PowerSecure und PSI geworfen. Bei der PSI AG überlege ich jetzt einzusteigen. Ich hatte zuletzt interessante Gespräche mit RWE Mitarbeitern (nicht die ganz hohe Führungsebene, aber schon etwas höhere Positionen) und dort setzt man voll auf Smart Grid. Darum habe sich RWE ja auch bei PSI eingekauft. Und auch Cisco Systems oder General Electric wollen ja in diesem Markt ein Wörtchen mitreden.

Kurz zu Echelon: Ein Umsatz von knapp 117 Mio. US$ (2008) wird dort derzeit mit einer Market Cap. von knapp 370 Mio. US$ bezahlt, ergo ein KUV von etwas über 3. Bisher schreibt die Firma zwar noch rote Zahlen (EBITDA: -23,66 Mio. US$), aber ich denke die Gewinnschwelle ist nicht mehr so fern. Und mit knapp 88 Mio. US$ Cash ist man gut durchfinanziert. Deshalb habe ich mich bisher für Echelon entschieden, zumal mir deren Technologie gefällt und mich auch der Chart überzeugt hat. Was meint Ihr zu Echelon?

LG Enzo

PS: Mehr Infos zu Echelon gibts auch unter: http://tr.im/utkQ

Hallo,

ich bin auf diesen Smart Grid Thread aufmerksam geworden. Leider ist er nicht gerade gut besucht.

Bin selber in Echelon und diversen anderen investiert.

Eigentlich schade das die Aktien der Zukunft die die Internetaktien und die Photovoltaikaktien ablösen werden so wenig besucht bzw. diskutiert werden.

Aber es ist schön mal von anfang an dabei zu sein.

ich bin auf diesen Smart Grid Thread aufmerksam geworden. Leider ist er nicht gerade gut besucht.

Bin selber in Echelon und diversen anderen investiert.

Eigentlich schade das die Aktien der Zukunft die die Internetaktien und die Photovoltaikaktien ablösen werden so wenig besucht bzw. diskutiert werden.

Aber es ist schön mal von anfang an dabei zu sein.

Meine Favoriten sind klar Comverge und Echelon.

aus einem neuen Report von GTM:

1.3.1 Power-oriented (“fast”) energy storage will grow quickly in the near to mid

term but will be constrained in the long term by a modest total market size.

Power-oriented (“fast”) energy storage is poised for strong near- to mid-term growth.

Its most signifi cant component, the frequency regulation market, has recently been

opened up for direct entry by energy storage in some ISO regions of the U.S. with

additional ISOs anticipated. This means that energy storage can secure contracts for

grid frequency regulation on the open market and the owner of the system will get compensated in cash. This capture-able, all cash benefi t stream makes obtaining

compensation for an energy storage system much less complicated than many other

implementations. New highly robust, moderate cost lithium-ion batteries are able to

provide this service cost effectively and are beginning to be deployed successfully in a

few regions of the U.S. and in Chile. This trend is expected to continue and accelerate

with the addition of new renewable resources on the grid and further decreases in the

cost of lithium-ion batteries. Production of fast energy storage in 2009 is estimated at

49 MW and is expected to grow to 479 MW or $500 million in 2015. The total market

size for fast energy storage is estimated at about 7,137 MW total for the U.S. and

about 37,828 MW for the world.

1.3.2 Energy-oriented (load shifting) energy storage has a massive total market

size, however it is only beginning to be ready to be exploited.

Energy-oriented (load shifting) energy storage offers a number of potentially lucrative

opportunities for implementations that strategically combine applications. While

wholesale load shifting is sometimes discussed, it does not create enough value to

be cost effective on its own in most situations right now. There are, however, many

existing strategic load shifting implementations that are or nearly are cost effective.

The challenge with these implementations is that some of the benefi ts are generated

as non-cash benefi ts which can be diffi cult to monetize or the benefi ts come from

bundling different value streams, which are feasible technically but challenging to

accrue to one entity for regulatory reasons. In some parts of the world, like Japan,

where the value created from single applications is higher or utilities are more easily

able to accrue value from the multiple benefi ts generated, sodium sulfur (NaS) load

shifting energy storage has already gained a good foothold and has recently gained

favor in other countries like France and the UAE, though only small pilot installations

exist in the U.S. New fl ow battery technology, particularly zinc-bromide, has recently

become more cost effective than NaS for many implementations and is expected

to grow to surpass NaS installations by 2015. Advanced lead acid batteries are

also expected to show impressive growth due to further cost reduction and plentiful

installed manufacturing capacity able to be repurposed from traditional lead acid

batteries. The currently variable government regulation climate for LS storage is

expected to somewhat limit near-term growth, but more amenable regulation and

mass production cost reduction for LS storage are expected to drive strong mid to

long term growth. In 2009, an estimated 151 MW were produced, but in 2015, 1,066

MW are expected to be produced with revenues of $1,596 million. The total market

size is estimated at 85,000 MW in the U.S. and 450,000 MW in the world.

1.3.3 Government regulation will play a large role in determining the rate of the roll

out of all energy storage.

Government regulation is a critical driver of or inhibitor to energy storage technology

penetrating the market. Recent history and current trends in government regulation

are favorable for energy storage, especially for frequency regulation in the U.S. Recent

political action in favor of renewable power, including energy storage tax incentives

in bill S.1091 recently proposed in the U.S. Congress, is paving the way for a more

favorable environment for LS in the U.S. However, compensation for utilities will also

have to change in order to fully spur progress for LS energy storage, including areas

like allowable inclusions in the rate base, risk compensation and ownership of assets

useful for both T&D and generation. Other countries with differing structures for utility

compensation and greater LS storage penetration, like Japan, France and the UAE,

may offer ideas for how to encourage its penetration in the U.S.

1.3.1 Power-oriented (“fast”) energy storage will grow quickly in the near to mid

term but will be constrained in the long term by a modest total market size.

Power-oriented (“fast”) energy storage is poised for strong near- to mid-term growth.

Its most signifi cant component, the frequency regulation market, has recently been

opened up for direct entry by energy storage in some ISO regions of the U.S. with

additional ISOs anticipated. This means that energy storage can secure contracts for

grid frequency regulation on the open market and the owner of the system will get compensated in cash. This capture-able, all cash benefi t stream makes obtaining

compensation for an energy storage system much less complicated than many other

implementations. New highly robust, moderate cost lithium-ion batteries are able to

provide this service cost effectively and are beginning to be deployed successfully in a

few regions of the U.S. and in Chile. This trend is expected to continue and accelerate

with the addition of new renewable resources on the grid and further decreases in the

cost of lithium-ion batteries. Production of fast energy storage in 2009 is estimated at

49 MW and is expected to grow to 479 MW or $500 million in 2015. The total market

size for fast energy storage is estimated at about 7,137 MW total for the U.S. and

about 37,828 MW for the world.

1.3.2 Energy-oriented (load shifting) energy storage has a massive total market

size, however it is only beginning to be ready to be exploited.

Energy-oriented (load shifting) energy storage offers a number of potentially lucrative

opportunities for implementations that strategically combine applications. While

wholesale load shifting is sometimes discussed, it does not create enough value to

be cost effective on its own in most situations right now. There are, however, many

existing strategic load shifting implementations that are or nearly are cost effective.

The challenge with these implementations is that some of the benefi ts are generated

as non-cash benefi ts which can be diffi cult to monetize or the benefi ts come from

bundling different value streams, which are feasible technically but challenging to

accrue to one entity for regulatory reasons. In some parts of the world, like Japan,

where the value created from single applications is higher or utilities are more easily

able to accrue value from the multiple benefi ts generated, sodium sulfur (NaS) load

shifting energy storage has already gained a good foothold and has recently gained

favor in other countries like France and the UAE, though only small pilot installations

exist in the U.S. New fl ow battery technology, particularly zinc-bromide, has recently

become more cost effective than NaS for many implementations and is expected

to grow to surpass NaS installations by 2015. Advanced lead acid batteries are

also expected to show impressive growth due to further cost reduction and plentiful

installed manufacturing capacity able to be repurposed from traditional lead acid

batteries. The currently variable government regulation climate for LS storage is

expected to somewhat limit near-term growth, but more amenable regulation and

mass production cost reduction for LS storage are expected to drive strong mid to

long term growth. In 2009, an estimated 151 MW were produced, but in 2015, 1,066

MW are expected to be produced with revenues of $1,596 million. The total market

size is estimated at 85,000 MW in the U.S. and 450,000 MW in the world.

1.3.3 Government regulation will play a large role in determining the rate of the roll

out of all energy storage.

Government regulation is a critical driver of or inhibitor to energy storage technology

penetrating the market. Recent history and current trends in government regulation

are favorable for energy storage, especially for frequency regulation in the U.S. Recent

political action in favor of renewable power, including energy storage tax incentives

in bill S.1091 recently proposed in the U.S. Congress, is paving the way for a more

favorable environment for LS in the U.S. However, compensation for utilities will also

have to change in order to fully spur progress for LS energy storage, including areas

like allowable inclusions in the rate base, risk compensation and ownership of assets

useful for both T&D and generation. Other countries with differing structures for utility

compensation and greater LS storage penetration, like Japan, France and the UAE,

may offer ideas for how to encourage its penetration in the U.S.

Antwort auf Beitrag Nr.: 37.871.717 von R-BgO am 28.08.09 12:02:39und diese Firmen werden im Report behandelt (die unterstrichenen habe ich im Depot):

6 APPENDICES 92

6.1 Industry Roster – Zinc Bromide Flow Batteries 92

6.1.1 Net Power Technology 92

6.1.2 Premium Power 93

6.1.3 RedFlow 95

6.1.4 ZBB Energy 97

6.2 Industry Roster – Vanadium Redox Flow Batteries 99

6.2.1 Cellenium 99

6.2.2 Cellstrom 100

6.2.3 Prudent Energy [formerly VRB Power Inc. and Sumitomo Electric Industries (SEI)] 101

6.3 Industry Roster – Other Flow Batteries 104

6.3.1 Deeya 104

6.3.2 EnerVault 105

6.3.3 EnStorage

6.3.4 Plurion Systems 107

6.3.5 Primus Power Corporation 108

6.4 Industry Roster – Advanced Lead Acid Batteries 109

6.4.1 Axion Power International/Exide 109

6.4.2 C&D Technologies 111

6.4.3 East Penn/Furukawa 112

6.4.4 Other Advanced Lead Acid Battery Manufacturers 113

6.5 Industry Roster – Sodium Batteries 113

6.5.1 General Electric 113

6.5.2 NGK Insulators 114

6.6 Industry Roster – Lithium-Ion Batteries 117

6.6.1 A123 Systems 117

6.6.2 Altair Nanotechnologies 119

6.6.3 BYD Company Limited 121

6.6.4 Saft 122

6.6.5 Valance 124

6.6.6 Other Lithium-Ion Battery Manufacturers 125

6.7 Industry Roster – Lithium-Air Batteries 125

6.7.1 IBM 125

6.8 Industry Roster – Flywheels 126

6.8.1 Beacon Power 126

6.8.2 Pentadyne 128

6.8.3 Power Tree 129

6.8.4 Other Flywheel Manufacturers

6 APPENDICES 92

6.1 Industry Roster – Zinc Bromide Flow Batteries 92

6.1.1 Net Power Technology 92

6.1.2 Premium Power 93

6.1.3 RedFlow 95

6.1.4 ZBB Energy 97

6.2 Industry Roster – Vanadium Redox Flow Batteries 99

6.2.1 Cellenium 99

6.2.2 Cellstrom 100

6.2.3 Prudent Energy [formerly VRB Power Inc. and Sumitomo Electric Industries (SEI)] 101

6.3 Industry Roster – Other Flow Batteries 104

6.3.1 Deeya 104

6.3.2 EnerVault 105

6.3.3 EnStorage

6.3.4 Plurion Systems 107

6.3.5 Primus Power Corporation 108

6.4 Industry Roster – Advanced Lead Acid Batteries 109

6.4.1 Axion Power International/Exide 109

6.4.2 C&D Technologies 111

6.4.3 East Penn/Furukawa 112

6.4.4 Other Advanced Lead Acid Battery Manufacturers 113

6.5 Industry Roster – Sodium Batteries 113

6.5.1 General Electric 113

6.5.2 NGK Insulators 114

6.6 Industry Roster – Lithium-Ion Batteries 117

6.6.1 A123 Systems 117

6.6.2 Altair Nanotechnologies 119

6.6.3 BYD Company Limited 121

6.6.4 Saft 122

6.6.5 Valance 124

6.6.6 Other Lithium-Ion Battery Manufacturers 125

6.7 Industry Roster – Lithium-Air Batteries 125

6.7.1 IBM 125

6.8 Industry Roster – Flywheels 126

6.8.1 Beacon Power 126

6.8.2 Pentadyne 128

6.8.3 Power Tree 129

6.8.4 Other Flywheel Manufacturers

Alcatel-Lucent Your Smart Grid Partner:

http://www.mthink.com/utilities/alcatel-lucent-0

Programm des E-Energy Jahreskongresses 2009

Elektrizität ist das Rückgrat von Wirtschaft und Gesellschaft. Steigende Nachfrage, die Rohstoffverknappung und der Klimawandel stellen das Energiesystem vor große Herausforderungen.

Es müssen neue Lösungen gefunden werden, die den Anforderungen des Wandels zu liberalisierten Märkten, zu dezentralen und volatilen Erzeugungsstrukturen sowie zur Elektromobilität Rechnung tragen - und ein Höchstmaß an Wirtschaftlichkeit, Versorgungssicherheit und Umweltverträglichkeit sicherstellen. Informations- und Kommunikationstechnologien (IKT) werden dabei eine zentrale Rolle spielen: Mit ihrer Hilfe können intelligente Energiesysteme betrieben werden, in denen viele Erzeugungsanlagen - zunehmend auch solche mit erneuerbaren Energien - mit den Einrichtungen der Stromnetze und den Strom verbrauchenden Endgeräten kommunizieren.

Viele der Initiativen und Aktivitäten in diesem Bereich werden international unter dem Begriff "Smart Grids" zusammengefasst. "Smart" steht in diesem Zusammenhang für die intelligente Nutzung aller zur Verfügung stehenden Ressourcen sowie für die Optimierung und Integration des Gesamtsystems der Elektrizitätsversorgung - von der Gewinnung des Stroms über die Speicherung, den Transport, die Verteilung bis hin zur effizienten Verwendung.

In Deutschland werden die Smart Grid-Aktivitäten unter dem Dach der Förderinitiative "E-Energy - IKTbasiertes Energiesystem der Zukunft" gebündelt, die auf dem IT-Gipfel von der Bundeskanzlerin zum nationalen Leuchtturm-Projekt erklärt wurde. E-Energy - das heißt "Smart Grids - Made in Germany".

Donnerstag, 26. November 2009

14:00 Uhr

Eröffnung des E-Energy Jahreskongresses

Bundesministerium für Wirtschaft und Technologie

Grußworte seitens der Partnerländer:

- Eidgenössisches Departement für Umwelt, Verkehr, Energie und Kommunikation, Schweiz

- Bundesministeriums für Verkehr, Innovation und Technologie, Österreich

15:00 Uhr

Impulsvortrag

15:30 Uhr

Podiumsgespräch: Schöne neue Welt der IKT- und Energiewirtschaft?

- Dr. Werner Brinker, EWE AG, Vorsitzender des Vorstands

- Prof. Henning Kagermann, acatech - Deutsche

Akademie der Technikwissenschaft e. V., Präsident

- Dr. Holger Krawinkel, Bundesverband Verbraucherzentralen e. V.

- Dr. Jochen Kreusel, Energietechnische Gesellschaft (ETG) im VDE, Vorstand

- Dr. Rudolf Strohmeier, EU Kommission

- Dr. Christian Urbanke, Bundesverband der Deutschen Industrie e. V.

- Alf Henryk Wulf, Alcatel-Lucent-Deutschland AG

http://www.mthink.com/utilities/alcatel-lucent-0

Programm des E-Energy Jahreskongresses 2009

Elektrizität ist das Rückgrat von Wirtschaft und Gesellschaft. Steigende Nachfrage, die Rohstoffverknappung und der Klimawandel stellen das Energiesystem vor große Herausforderungen.

Es müssen neue Lösungen gefunden werden, die den Anforderungen des Wandels zu liberalisierten Märkten, zu dezentralen und volatilen Erzeugungsstrukturen sowie zur Elektromobilität Rechnung tragen - und ein Höchstmaß an Wirtschaftlichkeit, Versorgungssicherheit und Umweltverträglichkeit sicherstellen. Informations- und Kommunikationstechnologien (IKT) werden dabei eine zentrale Rolle spielen: Mit ihrer Hilfe können intelligente Energiesysteme betrieben werden, in denen viele Erzeugungsanlagen - zunehmend auch solche mit erneuerbaren Energien - mit den Einrichtungen der Stromnetze und den Strom verbrauchenden Endgeräten kommunizieren.

Viele der Initiativen und Aktivitäten in diesem Bereich werden international unter dem Begriff "Smart Grids" zusammengefasst. "Smart" steht in diesem Zusammenhang für die intelligente Nutzung aller zur Verfügung stehenden Ressourcen sowie für die Optimierung und Integration des Gesamtsystems der Elektrizitätsversorgung - von der Gewinnung des Stroms über die Speicherung, den Transport, die Verteilung bis hin zur effizienten Verwendung.

In Deutschland werden die Smart Grid-Aktivitäten unter dem Dach der Förderinitiative "E-Energy - IKTbasiertes Energiesystem der Zukunft" gebündelt, die auf dem IT-Gipfel von der Bundeskanzlerin zum nationalen Leuchtturm-Projekt erklärt wurde. E-Energy - das heißt "Smart Grids - Made in Germany".

Donnerstag, 26. November 2009

14:00 Uhr

Eröffnung des E-Energy Jahreskongresses

Bundesministerium für Wirtschaft und Technologie

Grußworte seitens der Partnerländer:

- Eidgenössisches Departement für Umwelt, Verkehr, Energie und Kommunikation, Schweiz

- Bundesministeriums für Verkehr, Innovation und Technologie, Österreich

15:00 Uhr

Impulsvortrag

15:30 Uhr

Podiumsgespräch: Schöne neue Welt der IKT- und Energiewirtschaft?

- Dr. Werner Brinker, EWE AG, Vorsitzender des Vorstands

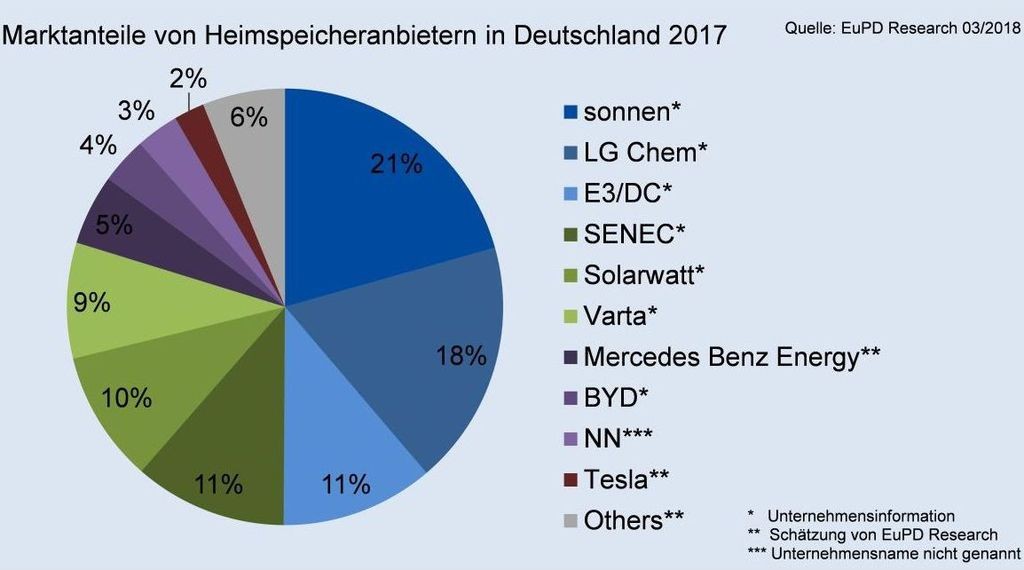

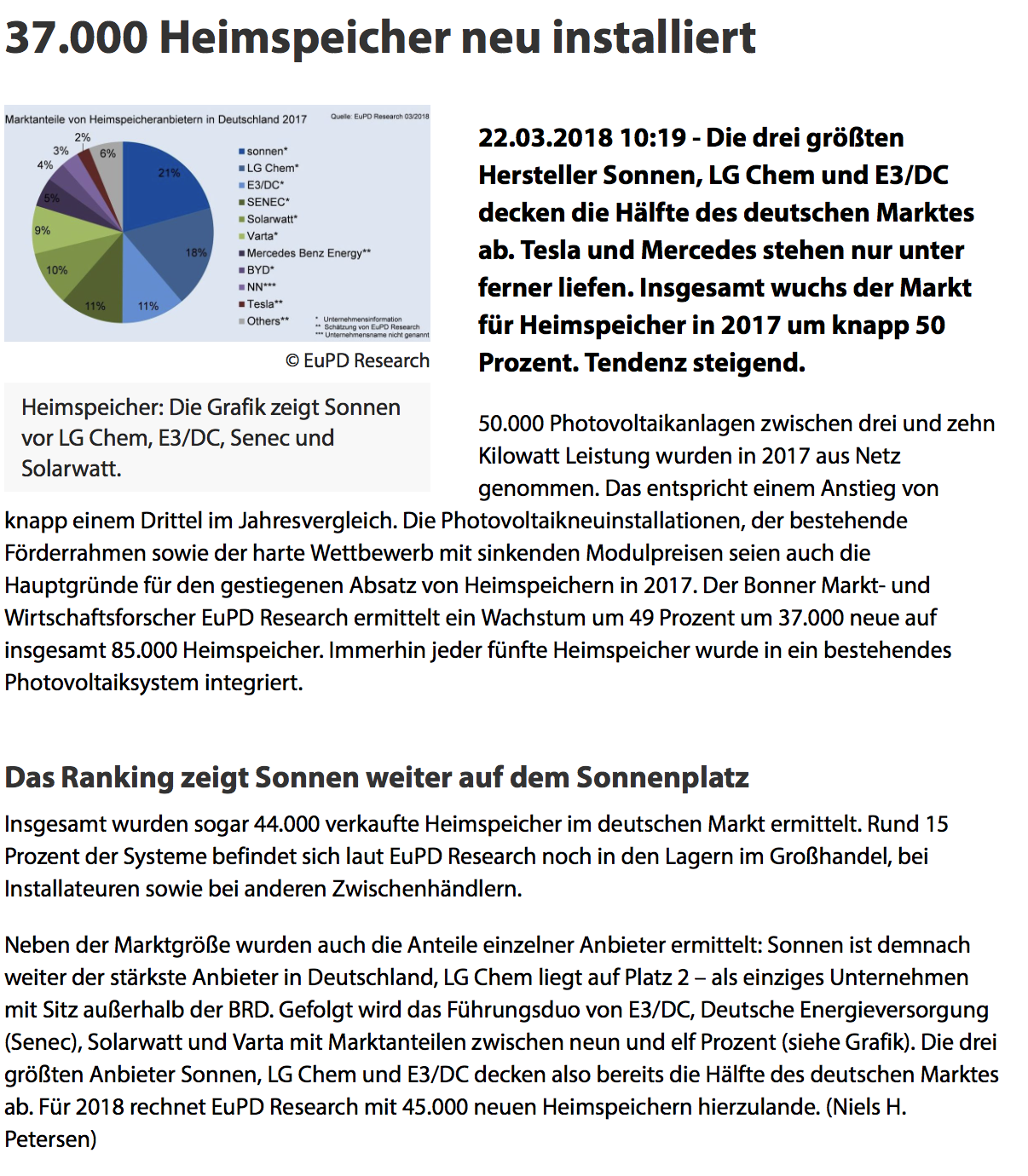

- Prof. Henning Kagermann, acatech - Deutsche